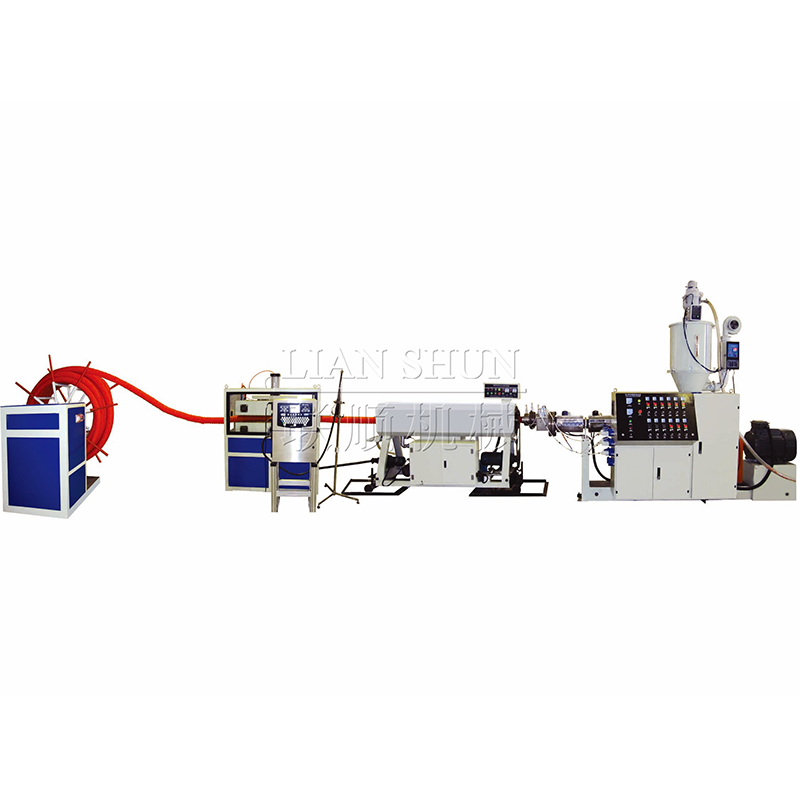

High-Quality Electric PVC Pipe Making Machine: What You Need to Know

By:Admin

The electric PVC pipe making machine is a modern and efficient solution for producing high-quality PVC pipes. With its advanced technology and user-friendly design, this machine has the capability to produce a wide range of PVC pipes with varying diameters and thicknesses. It is also equipped with an automatic control system, ensuring accurate and precise production of pipes.

The machine's production capacity is impressive, as it is capable of producing a large number of PVC pipes in a short amount of time. This not only increases efficiency but also reduces production costs, making it an attractive option for manufacturers looking to streamline their operations.

One of the key features of the electric PVC pipe making machine is its energy efficiency. By using electricity as its power source, this machine significantly reduces energy consumption compared to traditional PVC pipe making machines. This not only benefits the environment but also helps manufacturers save on energy costs in the long run.

In addition to its impressive performance, the electric PVC pipe making machine is also known for its durability and reliability. Built with high-quality materials and state-of-the-art components, this machine is designed to withstand rigorous production processes and deliver consistent results over time. This makes it a valuable investment for manufacturers seeking a long-term solution for their PVC pipe production needs.

{Company Name} is a leading manufacturer in the field of industrial machinery, with a strong reputation for innovation and excellence. With a focus on research and development, the company has consistently introduced cutting-edge technologies and solutions to meet the evolving needs of the manufacturing industry.

The development of the electric PVC pipe making machine is a testament to {Company Name}'s commitment to providing high-quality and sustainable solutions for its customers. By leveraging its expertise in industrial machinery, the company has successfully designed and manufactured a machine that is poised to revolutionize the production of PVC pipes.

{Company Name} has a strong track record of delivering reliable and efficient machinery to its clients, and the electric PVC pipe making machine is no exception. With its advanced features and capabilities, this machine is expected to set a new industry standard for PVC pipe production, and {Company Name} is proud to be at the forefront of this innovation.

As the demand for PVC pipes continues to grow, manufacturers are constantly seeking ways to improve their production processes and meet the needs of their customers. The electric PVC pipe making machine from {Company Name} is a timely and valuable solution that is set to make a significant impact on the industry.

In conclusion, the electric PVC pipe making machine is a groundbreaking technology that is set to transform the manufacturing of PVC pipes. With its advanced features, energy efficiency, and reliable performance, this machine offers a valuable solution for manufacturers seeking to streamline their production processes and deliver high-quality pipes to their customers. {Company Name} has once again demonstrated its leadership in the field of industrial machinery by introducing this innovative and game-changing technology to the market.

Company News & Blog

The Ultimate Guide to the Cost of Extruder Machines in 2021

[Company Introduction][Company Name] is a leading manufacturer of industrial machinery and equipment, with a strong focus on providing high-quality solutions for the plastic processing industry. With years of experience and a commitment to innovation, [Company Name] has established itself as a trusted partner for businesses looking to enhance their production capabilities.[Company Name] offers a wide range of products, including extruder machines, injection molding machines, and auxiliary equipment. The company's dedication to research and development has led to the creation of cutting-edge technology that delivers superior performance and efficiency. Furthermore, [Company Name] is known for its excellent customer service and support, ensuring that clients receive the guidance and assistance they need to optimize their manufacturing processes.[Cost Of Extruder Machine]The cost of an extruder machine is a significant investment for businesses in the plastic processing industry. The prices of these machines can vary depending on factors such as capacity, features, and technology. It is crucial for companies to carefully consider their production requirements and budget before making a purchase decision.[Company Name] understands the importance of offering competitive pricing for its extruder machines while maintaining the highest standards of quality and performance. The company's commitment to providing cost-effective solutions has made its products sought after by businesses worldwide.The cost of an extruder machine from [Company Name] typically ranges from $50,000 to $500,000, depending on the specific model and customization options. This pricing reflects the advanced technology and engineering that goes into each machine, as well as the company's dedication to meeting the diverse needs of its clients.There are several factors that contribute to the cost of an extruder machine, including the following:1. Capacity: The size of the extruder machine and its production capacity will influence its cost. Larger machines with higher output capabilities will generally come with a higher price tag.2. Features: Extruder machines can be equipped with a range of features, such as automation, precision control systems, and advanced material handling capabilities. These additional features can increase the overall cost of the machine.3. Technology: [Company Name] prides itself on incorporating the latest technological advancements into its extruder machines. The use of innovative technology can impact the pricing of the machines, as it enhances their performance and reliability.4. Customization: [Company Name] also offers customization options for its extruder machines, allowing businesses to tailor the equipment to their specific production needs. Customization may incur additional costs but can result in a more tailored and efficient manufacturing solution.Despite the initial investment required, businesses can benefit from the long-term cost savings and improved productivity that come with a high-quality extruder machine from [Company Name]. The company's machines are designed for durability and efficiency, helping clients to achieve consistent and high-quality production results while minimizing downtime and maintenance costs.In conclusion, the cost of an extruder machine from [Company Name] reflects the value and reliability that businesses can expect from this industry-leading manufacturer. With a focus on delivering cost-effective solutions without compromising on quality, [Company Name] continues to be a trusted partner for companies in the plastic processing industry.

High-quality WPC Making Machine for Efficient Production

WPC Making Machine revolutionizing the manufacturing industryIn the ever-evolving world of technology and innovation, the WPC Making Machine has emerged as a game-changer in the manufacturing industry. This advanced machine, developed by {}, has streamlined the process of producing Wood-Plastic Composite (WPC) materials, offering unprecedented efficiency, precision, and versatility.{} is a leading manufacturer of industrial machinery, renowned for its commitment to quality, innovation, and customer satisfaction. With a strong focus on research and development, the company has continually pushed the boundaries of what is possible in the manufacturing sector. The WPC Making Machine is a testament to {}'s dedication to pioneering new technologies that enhance productivity and drive progress.The WPC Making Machine is designed to meet the growing demand for WPC materials, which are widely used in construction, automotive, and consumer goods industries. By blending wood fibers or flour with thermoplastics, WPC materials offer the natural look and feel of wood combined with the durability and low maintenance of plastic. As a result, they have become a popular choice for a wide range of applications, from decking and fencing to furniture and packaging.One of the key advantages of the WPC Making Machine is its ability to precisely control the mixing and extrusion process, ensuring that the resulting WPC materials meet the highest standards of quality and consistency. This level of precision is made possible by {}'s cutting-edge technology, which enables real-time monitoring and adjustment of critical parameters such as temperature, pressure, and material flow. As a result, manufacturers can produce WPC materials with the exact properties required for their specific applications, whether it's enhanced strength, weather resistance, or colorfastness.Furthermore, the WPC Making Machine offers exceptional versatility, allowing for the production of a wide variety of WPC products, from simple profiles and sheets to more complex structures and composites. This flexibility is a major advantage for manufacturers seeking to tap into the growing market for WPC materials and capitalize on the trend towards sustainable and eco-friendly alternatives to traditional materials.In addition to its technical capabilities, the WPC Making Machine also stands out for its efficiency and cost-effectiveness. By automating and optimizing the production process, {} has enabled manufacturers to significantly reduce waste, energy consumption, and labor costs, while increasing throughput and overall productivity. This not only benefits individual businesses but also contributes to the industry's overall sustainability and competitiveness.As the demand for WPC materials continues to grow, driven by concerns about deforestation, plastic pollution, and the need for more sustainable solutions, the WPC Making Machine is poised to play a pivotal role in shaping the future of manufacturing. With its advanced capabilities, versatility, and efficiency, it offers a compelling solution for businesses looking to stay ahead of the curve and meet the evolving needs of customers and the market.{}'s commitment to innovation and excellence has positioned the company as a leader in the field of industrial machinery, and the WPC Making Machine is a prime example of its forward-thinking approach to product development. By empowering manufacturers to produce high-quality WPC materials with greater efficiency and versatility, this cutting-edge machine is driving the industry towards a more sustainable, profitable, and competitive future.

High-Density Polyethylene (HDPE) Extruder Machine Price: Factors to Consider

The demand for HDPE extruder machines has been on the rise due to the increasing use of high-density polyethylene (HDPE) in various industries. HDPE is a versatile material that is widely used in packaging, construction, automotive, and other sectors due to its strength, durability, and resistance to chemicals and moisture. As a result, companies are looking for reliable and efficient HDPE extruder machines to meet the growing demand for HDPE products.One company that has been making waves in the HDPE extruder machine market is {Company Name}. With years of experience and expertise in the field of plastic extrusion, they have been providing high-quality extruder machines to companies around the world. Their machines are known for their precision, reliability, and efficiency, making them a top choice for businesses looking to invest in a quality extrusion solution.One of the key factors that sets {Company Name} apart from its competitors is its commitment to innovation and continuous improvement. The company is constantly investing in research and development to stay ahead of the curve and offer the latest advancements in extrusion technology. As a result, their machines are not only efficient and reliable but also incorporate the latest technological advancements to enhance productivity and reduce operating costs.In addition to their focus on innovation, {Company Name} also prides itself on providing excellent customer service and support. They work closely with their clients to understand their specific needs and provide tailored solutions to meet their requirements. From installation and training to ongoing maintenance and support, the company is dedicated to ensuring that their clients get the most out of their investment in an HDPE extruder machine.As the demand for HDPE products continues to grow, {Company Name} has been ramping up production to meet the increasing demand for their extruder machines. In order to accommodate the growing interest in their products, the company has scaled up their manufacturing capabilities and streamlined their operations to ensure timely delivery and exceptional quality.Considering the increasing demand for HDPE extruder machines, {Company Name} has been considering the expansion of its product line to offer a wider range of options to its customers. This includes the development of new extruder models with enhanced features and capabilities to cater to the evolving needs of the industry. By diversifying their product offerings, the company aims to establish itself as a one-stop solution for businesses looking for reliable and efficient HDPE extrusion solutions.In terms of pricing, {Company Name} has been competitive in the market, offering their high-quality extruder machines at a fair and reasonable price point. They understand the importance of cost-effectiveness for their clients and strive to provide value for money with their products. Additionally, the company offers flexible payment options and financing solutions to make their machines accessible to a wide range of businesses, regardless of their size or budget.In conclusion, {Company Name} has solidified its position as a leading provider of HDPE extruder machines, thanks to its commitment to innovation, quality, and customer satisfaction. With a focus on continuous improvement and expansion, the company is well-positioned to meet the growing demand for extrusion solutions and support businesses in their quest for efficient and reliable HDPE production. For companies looking to invest in a top-quality extruder machine, {Company Name} remains a trusted and reliable partner in the industry.

New Pelletizing Plant Under Construction to Boost Production Capacity

Pelletizing Plant, a leading manufacturer in the field of industrial equipment, has recently announced the opening of a new state-of-the-art facility in [location]. This new plant is set to be the company's largest and most advanced production facility to date.Pelletizing Plant has been at the forefront of the industry for over 50 years, providing high-quality equipment and solutions for a wide range of industrial applications. The company is known for its commitment to innovation, quality, and customer satisfaction, and the opening of this new facility further solidifies its position as a leader in the industry.The new plant is strategically located in [location] to better serve the company's global customer base. With its advanced technological capabilities and increased production capacity, the facility will allow Pelletizing Plant to meet the growing demand for its products and expand its reach in key markets around the world.In addition to being the largest facility in the company's portfolio, the new plant is also one of the most advanced. It is equipped with the latest manufacturing technology and automation systems, allowing for increased efficiency and production speed. This will enable Pelletizing Plant to meet the needs of its customers with even greater speed and precision, while maintaining its high standards of quality.The company's CEO, [CEO's name], expressed excitement about the opening of the new facility, stating that it represents a significant milestone for Pelletizing Plant. He emphasized that the investment in the new plant reflects the company's commitment to providing the best possible products and services to its customers, while also driving innovation in the industry.The opening of the new plant is also expected to have a positive impact on the local economy. The facility will create hundreds of new jobs in [location], providing opportunities for skilled workers and contributing to the growth and development of the community.Pelletizing Plant is known for its dedication to sustainability and environmental responsibility, and the new facility is no exception. The company has implemented rigorous environmental and safety standards in the design and operation of the plant, ensuring that it will operate in an eco-friendly and sustainable manner.In conclusion, the opening of the new Pelletizing Plant facility represents an exciting development for the company and the industry as a whole. With its advanced technology, increased production capacity, and focus on sustainability, the plant is set to further solidify Pelletizing Plant's position as a leading manufacturer in the industrial equipment sector. This investment is not only a testament to the company's commitment to innovation and quality but also to its impact on the local community and the wider industry.

Highly Efficient Twin Screw Extruder Machine for Industrial Use

Twin Screw Extruder Machine – revolutionizing the manufacturing industryIn today’s rapidly evolving manufacturing industry, the need for efficient and advanced machinery is more crucial than ever. As the demand for high-quality products and efficient production processes continues to grow, companies are constantly on the lookout for cutting-edge technology that can help them stay ahead of the competition. This is where the Twin Screw Extruder Machine comes into play, offering state-of-the-art capabilities that are revolutionizing the manufacturing industry.Combining cutting-edge technology and advanced engineering, the Twin Screw Extruder Machine is redefining the way products are manufactured. With its unparalleled precision and efficiency, this innovative machine is helping companies across the globe streamline their production processes and deliver high-quality products to their customers.The Twin Screw Extruder Machine, developed by [Company Name], is designed to meet the diverse needs of modern manufacturing operations. Whether it’s in the food, plastics, pharmaceutical, or chemical industry, this versatile machine is capable of handling a wide range of materials and processes, making it an indispensable asset for any production facility.With its twin screw design, this machine offers superior mixing and compounding capabilities, allowing for precise control over the quality and consistency of the end product. This is particularly critical in industries where the slightest variation in product quality can result in significant consequences. By utilizing the Twin Screw Extruder Machine, companies can ensure that their products meet the strictest standards of quality and performance.Another key feature of the Twin Screw Extruder Machine is its flexibility and adaptability. Thanks to its modular design and customizable configurations, this machine can be tailored to meet the specific requirements of each individual production line. Whether it’s adjusting the screw configuration, changing the barrel design, or incorporating additional processing units, the Twin Screw Extruder Machine offers unparalleled flexibility, allowing companies to optimize their production processes and stay ahead of the curve.In addition to its advanced capabilities, the Twin Screw Extruder Machine also boasts an intuitive control system that simplifies operation and maintenance. With user-friendly interfaces and remote monitoring capabilities, operators can easily oversee the machine’s performance and make real-time adjustments as needed. This not only enhances the overall efficiency of the production process but also minimizes downtime and reduces the risk of errors and complications.Furthermore, the Twin Screw Extruder Machine is designed with sustainability in mind. By optimizing energy consumption and minimizing waste, this machine helps companies reduce their environmental footprint without compromising on performance or product quality. With the growing emphasis on sustainability and eco-friendly practices, the Twin Screw Extruder Machine is well-positioned to meet the evolving needs of the manufacturing industry.At [Company Name], we take great pride in developing cutting-edge solutions that empower companies to thrive in today’s competitive marketplace. With our innovative Twin Screw Extruder Machine, we are committed to reshaping the manufacturing landscape and setting new standards for quality, efficiency, and sustainability. Backed by our extensive industry expertise and unwavering dedication to excellence, we are confident that our Twin Screw Extruder Machine will continue to drive innovation and deliver tangible results for companies across the globe.As the manufacturing industry continues to evolve, the demand for advanced machinery and technology will only grow. With its unmatched capabilities and adaptability, the Twin Screw Extruder Machine is poised to play a pivotal role in shaping the future of manufacturing, enabling companies to exceed customer expectations and thrive in an increasingly competitive market.

High-Quality Plastic Extruder for Efficient Production

Plastic Extruder (name removed) Company, a leading manufacturer in the plastic extrusion industry, continues to make waves with its innovative and high-quality products. With a strong focus on research and development, the company has established itself as a pioneer in the field, providing cutting-edge solutions to meet the needs of various industries.The plastic extrusion process involves melting raw plastic material and shaping it into a continuous profile. This process is widely used in the production of a wide range of products, including pipes, tubing, and various plastic components. Plastic Extruder (name removed) Company has been at the forefront of this industry, constantly pushing the boundaries of what is possible with plastic extrusion technology.One of the key factors that sets Plastic Extruder (name removed) Company apart from its competitors is its commitment to innovation. The company invests heavily in research and development, constantly looking for new ways to improve its products and processes. This dedication to innovation has allowed Plastic Extruder (name removed) Company to stay ahead of the curve and maintain its position as a leader in the industry.In addition to its focus on innovation, Plastic Extruder (name removed) Company also takes great pride in the quality of its products. The company uses state-of-the-art manufacturing techniques and stringent quality control measures to ensure that its products meet the highest standards. This commitment to quality has earned Plastic Extruder (name removed) Company a reputation for reliability and excellence, further bolstering its position in the market.Furthermore, Plastic Extruder (name removed) Company places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, and then develops customized solutions to meet these needs. This customer-centric approach has helped Plastic Extruder (name removed) Company build strong and lasting relationships with its clients, further solidifying its position in the industry.One of the standout products from Plastic Extruder (name removed) Company is its range of high-performance plastic extruders. These extruders are known for their precision and efficiency, making them ideal for a wide range of applications. Whether it's producing complex profiles or simple tubing, Plastic Extruder (name removed) Company has the technology and expertise to deliver top-notch results.Another area where Plastic Extruder (name removed) Company excels is in its commitment to sustainability. The company recognizes the importance of environmental responsibility and has implemented various measures to minimize its impact on the environment. From reducing waste in the production process to using eco-friendly materials, Plastic Extruder (name removed) Company is dedicated to doing its part for the planet.Looking ahead, Plastic Extruder (name removed) Company shows no signs of slowing down. The company is constantly working on new developments and innovations, with an eye towards continuing to lead the way in the plastic extrusion industry. With its strong focus on innovation, quality, customer satisfaction, and sustainability, Plastic Extruder (name removed) Company is well-positioned to remain a dominant force in the industry for years to come.In conclusion, Plastic Extruder (name removed) Company continues to impress with its cutting-edge solutions and unwavering commitment to excellence. With a strong track record of innovation, quality, and customer satisfaction, the company is poised to maintain its position as a leader in the plastic extrusion industry. As the industry continues to evolve, Plastic Extruder (name removed) Company will undoubtedly be at the forefront, setting the standard for others to follow.

High-Quality Plastic Tube Making Machine for Efficient Production

The plastic industry is constantly evolving and innovating to meet the demands of various applications. In line with this, the latest innovation in plastic tube making machines has been introduced by a leading company in the industry.The plastic tube making machine, developed by the company, is designed to cater to the growing demand for high-quality plastic tubes in a wide range of industries including cosmetics, pharmaceuticals, food and beverages, and more. The machine is equipped with state-of-the-art technology to ensure precision, efficiency, and reliability in the production of plastic tubes.One of the key features of this machine is its ability to produce plastic tubes of various sizes and specifications, making it extremely versatile for different applications. This flexibility is crucial for meeting the diverse needs of customers in the market.In addition to its versatility, the machine is also designed for high-speed production, allowing for increased output and faster lead times. This is particularly important for industries that require large quantities of plastic tubes within short periods of time.Furthermore, the plastic tube making machine is built with user-friendly controls and interface, making it easy for operators to set up and operate the machine with minimal training. This efficiency in operation is critical for businesses to streamline their production processes and maximize productivity.The company behind this innovative machine is a renowned leader in the plastic industry with a strong reputation for delivering high-quality and reliable machinery. With years of experience and expertise in the industry, the company has continuously pushed the boundaries of innovation to provide cutting-edge solutions for their customers.Their commitment to research and development has led to the creation of this advanced plastic tube making machine, which is set to revolutionize the way plastic tubes are manufactured. By leveraging the latest technology and engineering capabilities, the company has once again demonstrated its dedication to meeting the evolving needs of the plastic industry.Moreover, the company is known for its excellent customer support and after-sales service, ensuring that their customers receive the necessary assistance and guidance throughout the machine's lifecycle. This level of support is invaluable for businesses looking to invest in new machinery and technologies.In conclusion, the introduction of the new plastic tube making machine by this leading company represents a significant advancement in the plastic industry. With its versatility, speed, and user-friendly design, the machine is poised to meet the growing demands for high-quality plastic tubes across various sectors. As the industry continues to evolve, it is innovations like these that drive the progress and development of the plastic industry.

Discover the Latest Trends in Mixer Vertical Technology

Mixer Vertical, a leading company in the field of kitchen appliances, has recently made a significant impact on the market with their latest innovative products. The company has been founded with a vision to revolutionize the way people cook and prepare food at home. Their dedication to craftsmanship and quality has set them apart in the industry, and their latest mixer vertical is no exception.This state-of-the-art mixer vertical is designed to make cooking and baking easier and more efficient for consumers. It's equipped with powerful motors and durable, stainless steel blades that can handle even the toughest ingredients, giving users a smooth and consistent blend every time. The mixer also features a variety of speed settings, allowing for precise control over the consistency of the mixture. This level of versatility makes it the perfect tool for a wide range of recipes, from smoothies and shakes to soups and sauces.One of the key features of this mixer vertical is its sleek and modern design. The company has paid close attention to the aesthetics of the product, ensuring that it not only performs well but also looks great on the kitchen counter. The mixer is available in a range of stylish colors, allowing consumers to choose a model that best suits their personal taste and kitchen decor.In addition to its performance and design, the mixer vertical also boasts a number of practical features that make it a joy to use. Its large capacity bowl can hold a substantial amount of ingredients, reducing the need for multiple batches when preparing large quantities of food. The mixer is also easy to clean, with removable parts that can be quickly and easily washed by hand or in the dishwasher.The company's dedication to quality and customer satisfaction is evident in the reception of their products. Customers have praised the mixer vertical for its exceptional performance, durability, and user-friendly design. Many have also noted the company's commitment to providing excellent customer service, further solidifying their reputation as a trusted and reliable brand.In addition to the mixer vertical, the company offers a wide range of kitchen appliances and accessories to meet the needs of home cooks and professional chefs alike. From blenders and food processors to coffee makers and electric kettles, their product line is designed to make cooking and food preparation as convenient and enjoyable as possible.While the mixer vertical has already made a significant impact on the market, the company shows no signs of slowing down. They continue to innovate and develop new products, constantly seeking to improve the cooking experience for their customers. With a strong focus on quality, performance, and design, Mixer Vertical is poised to remain a leader in the industry for years to come.In conclusion, Mixer Vertical has established itself as a top player in the kitchen appliance industry, thanks to its dedication to quality, innovation, and customer satisfaction. Their latest mixer vertical is a testament to their commitment to excellence, offering consumers a powerful and stylish tool for all their blending and mixing needs. As they continue to grow and expand their product line, it's clear that Mixer Vertical is a brand to watch in the world of kitchen appliances.

Top Tips for Mixing Hot and Cold Water Properly

Mixer Hot And Cold, a leading company in the home appliance industry, has recently introduced their latest innovation in the field of kitchen appliances. The company, known for its high-quality and reliable products, has once again raised the bar with their new mixer that offers both hot and cold functions in one compact and efficient design.The new mixer, which is designed to meet the needs of modern households, is equipped with advanced technology that allows users to effortlessly switch between hot and cold settings with just the push of a button. This innovative feature not only saves time and effort, but also adds a new level of convenience to everyday cooking and baking tasks.One of the key advantages of Mixer Hot And Cold's latest offering is its ability to cater to a wide range of culinary needs. Whether it's whipping up a batch of homemade ice cream on a hot summer day or preparing a steaming hot soup for a cozy winter evening, this versatile mixer has the capabilities to handle it all. This level of adaptability makes it an invaluable addition to any kitchen, especially for those who love experimenting with different recipes and flavors.In addition to its practicality, the new mixer also boasts a sleek and modern design that is sure to complement any kitchen decor. Its compact size and user-friendly interface make it a perfect fit for both small and large spaces, while its durable construction ensures long-lasting performance for years to come.Furthermore, Mixer Hot And Cold has always been committed to sustainability and environmental responsibility. The new mixer is no exception, as it is designed with energy-efficient features that help reduce overall energy consumption. This aligns with the company's dedication to promoting eco-friendly solutions without compromising on quality and performance.With the launch of their latest innovation, Mixer Hot And Cold continues to solidify its position as a frontrunner in the home appliance industry. The company's reputation for delivering top-notch products that cater to the evolving needs of consumers has only been further reinforced with this new addition to their lineup.In a statement, the CEO of Mixer Hot And Cold expressed his excitement about the launch of the new mixer, stating, "We are thrilled to introduce this game-changing product to our customers. The hot and cold capabilities of this mixer are a testament to our relentless pursuit of innovation and excellence. We believe that this new addition will not only simplify the cooking and baking process, but also inspire creativity in the kitchen."The introduction of Mixer Hot And Cold's latest innovation has already generated a buzz in the industry, with early reviews praising its functionality and performance. As consumers increasingly seek products that offer practicality, versatility, and reliability, it is evident that this new mixer has arrived at the perfect time to meet these demands.In conclusion, Mixer Hot And Cold's new hot and cold mixer represents a significant leap forward in the realm of kitchen appliances. Its innovative features, modern design, and commitment to sustainability make it a noteworthy addition to the company's esteemed product portfolio. As the demand for efficient and multi-functional appliances continues to grow, Mixer Hot And Cold's latest offering is well-poised to make a meaningful impact in the market.

High-Quality Single Screw Plastic Extruder Machine for Sale

Single Screw Plastic Extruder Machine revolutionizes plastic extrusion industryPlastic extrusion is a crucial process in the manufacturing industry, used to create a wide range of plastic products such as pipes, tubing, and profiles. The process involves melting raw plastic material and then shaping it into a continuous profile using a die. One of the key components in the extrusion process is the extruder machine, which provides the necessary force and heat to melt and shape the plastic material.In recent years, the plastic extrusion industry has seen significant advancements in technology, particularly in the development of more efficient and versatile extruder machines. One such innovation is the Single Screw Plastic Extruder Machine, which has been making waves in the industry with its cutting-edge design and superior performance.The Single Screw Plastic Extruder Machine, developed by a leading manufacturer, is designed to meet the demands of modern plastic extrusion processes. With its innovative single screw design, the machine is capable of extruding a wide range of plastic materials, including PVC, PE, PP, and more. This versatility makes it an ideal choice for manufacturers looking to produce different types of plastic products with a single machine.The machine also features an advanced heating and cooling system, which ensures precise and consistent temperature control during the extrusion process. This is vital for achieving high-quality and uniform plastic products, as fluctuations in temperature can lead to defects and inconsistencies in the final product.Furthermore, the Single Screw Plastic Extruder Machine is equipped with a state-of-the-art control system, which allows for easy and precise adjustments to the extrusion process. This level of control is essential for manufacturers who require flexibility in their production processes, as it enables them to fine-tune the machine to meet their specific requirements.In addition to its superior performance, the Single Screw Plastic Extruder Machine is also designed with efficiency in mind. With its energy-efficient operation and minimal maintenance requirements, the machine helps manufacturers reduce their operating costs while boosting their productivity.With these advanced features, the Single Screw Plastic Extruder Machine has quickly become a top choice for manufacturers in the plastic extrusion industry. Its ability to deliver high-quality, uniform products with efficiency and versatility has earned it a reputation as a game-changer in the industry.The company behind the Single Screw Plastic Extruder Machine is a renowned manufacturer of plastic processing equipment, with a strong track record of innovation and excellence. With a focus on research and development, the company has consistently pushed the boundaries of what is possible in plastic extrusion technology, resulting in the creation of cutting-edge machines like the Single Screw Plastic Extruder.The company's commitment to quality and customer satisfaction has also set it apart in the industry. With a team of experienced engineers and technicians, the company provides comprehensive support to its customers, ensuring that they get the most out of their equipment. Whether it's technical assistance, spare parts, or training, the company is dedicated to meeting the needs of its clients and helping them succeed in their businesses.Looking ahead, the company continues to invest in R&D to further enhance its range of plastic extrusion machines, with a focus on improving efficiency, versatility, and sustainability. By staying at the forefront of technological advancements, the company aims to remain a leader in the industry and continue to provide innovative solutions to its customers.As the demand for high-quality plastic products continues to grow, the Single Screw Plastic Extruder Machine is well-positioned to play a pivotal role in shaping the future of the plastic extrusion industry. With its unparalleled performance, efficiency, and versatility, the machine is set to revolutionize the way plastic products are manufactured, paving the way for a more sustainable and efficient manufacturing process.