New Plastic Shredder Technology Promises to Reduce Waste and Improve Recycling Efforts

By:Admin

In the fight against plastic pollution, new technologies and solutions are constantly being developed to reduce the environmental impact of plastic waste. One such innovative solution is the introduction of Shredder Plastic, a pioneering company that is revolutionizing the way plastic is recycled and repurposed. With a commitment to sustainability and environmental responsibility, Shredder Plastic has developed a state-of-the-art shredding technology that is capable of processing and transforming plastic waste into valuable recycled materials.

Shredder Plastic is at the forefront of the circular economy, which aims to minimize waste and maximize the value of resources through sustainable production and consumption. The company's cutting-edge shredding technology is able to process various types of plastic waste, including PET, HDPE, PVC, and more, and transform them into high-quality shredded plastic materials that can be used in the production of new plastic products. This innovative approach not only reduces the amount of plastic going to landfills and incinerators but also helps to lessen the demand for virgin plastic production, thereby conserving natural resources and reducing energy consumption.

With a strong focus on sustainability, Shredder Plastic is committed to delivering environmentally friendly solutions that meet the growing demand for recycled plastics in various industries. By providing a reliable source of high-quality shredded plastic materials, the company is helping businesses and manufacturers meet their sustainability goals and reduce their environmental footprint. Whether it's for packaging, construction, automotive, or consumer goods, Shredder Plastic is able to supply recycled plastic materials that meet the required specifications and standards, while also promoting a circular approach to plastic usage and disposal.

In addition to its advanced shredding technology, Shredder Plastic also offers comprehensive recycling and waste management services to businesses and organizations looking to improve their sustainability practices. The company provides customized solutions for collecting, sorting, and processing plastic waste, as well as designing and implementing recycling programs that help divert plastic from landfills and promote a more sustainable approach to waste management. By partnering with Shredder Plastic, businesses can effectively reduce their environmental impact and contribute to the overall effort to combat plastic pollution.

Shredder Plastic's commitment to sustainability and environmental responsibility extends beyond its products and services. The company also invests in research and development to continuously improve its shredding technology and explore new ways to enhance the efficiency and effectiveness of plastic recycling. By staying at the forefront of technological innovation, Shredder Plastic is able to adapt to the evolving needs of the recycling industry and drive positive change in the way plastic waste is managed and utilized.

As the demand for sustainable solutions continues to grow, Shredder Plastic is well-positioned to play a significant role in the global effort to reduce plastic waste and promote a more circular economy. With its advanced shredding technology, comprehensive recycling services, and commitment to innovation and sustainability, the company is making a meaningful contribution to the transition towards a more sustainable and responsible approach to plastic usage and disposal.

In conclusion, the introduction of Shredder Plastic represents a significant step forward in the fight against plastic pollution and the promotion of a more circular economy. With its advanced shredding technology, commitment to sustainability, and comprehensive recycling services, the company is leading the way in providing innovative solutions to reduce the environmental impact of plastic waste. By partnering with Shredder Plastic, businesses and organizations can make a positive contribution to the global effort to combat plastic pollution and promote a more sustainable approach to plastic usage and recycling.

Company News & Blog

High-Quality Profile Extrusion Machine for WPC Production

The latest technology in WPC (wood plastic composite) profile extrusion machines has been developed by a leading manufacturer in the industry. This cutting-edge technology promises to revolutionize the production of WPC profiles, offering higher efficiency, better quality, and enhanced capabilities for meeting the demands of the market.The new WPC profile extrusion machine incorporates state-of-the-art features that set it apart from traditional extrusion machines. It is equipped with advanced control systems and precision engineering to ensure a high level of accuracy and consistency in the production process. This results in WPC profiles that have superior dimensional stability, a smoother surface finish, and better overall performance.One of the key advantages of this new machine is its ability to handle a wide range of WPC materials, including different types of wood fibers and plastic resins. This flexibility allows manufacturers to create a variety of WPC profiles with varying characteristics, such as color, texture, and strength. It also enables them to tailor their production to meet specific requirements and market trends, giving them a competitive edge in the industry.In addition to its advanced capabilities, the new WPC profile extrusion machine is designed with efficiency in mind. It features a streamlined production process that minimizes waste and reduces energy consumption, leading to cost savings for manufacturers. Furthermore, its user-friendly interface and automated controls make it easy to operate and maintain, ensuring smooth and trouble-free production runs.The company behind this innovative WPC profile extrusion machine is a renowned leader in the field of plastic extrusion technology. With decades of experience and a strong commitment to research and development, they have earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the industry. Their team of engineers and technicians is dedicated to pushing the boundaries of what is possible in extrusion technology, and this latest innovation is a testament to their ongoing efforts.The company's dedication to quality and innovation extends beyond the products they offer. They also provide comprehensive support and technical assistance to their customers, ensuring that they get the most out of their investment in the new WPC profile extrusion machine. From installation and training to maintenance and troubleshooting, the company's team is readily available to help their customers achieve optimal performance and results.As a leading provider of WPC profile extrusion machines, the company has a global presence and serves a diverse range of industries, including construction, automotive, and consumer goods. Their technology is trusted by manufacturers around the world to deliver high-quality WPC profiles for a wide variety of applications. With the introduction of this new machine, they aim to raise the bar even higher and set new standards for excellence in WPC profile production.In conclusion, the new WPC profile extrusion machine from this leading manufacturer represents a significant advancement in extrusion technology. Its advanced features, versatility, efficiency, and quality make it a game-changer for the production of WPC profiles, empowering manufacturers to create innovative and high-performance products for their customers. With a track record of excellence and a commitment to customer satisfaction, the company is poised to make a lasting impact on the WPC industry with this groundbreaking technology.

High-Quality Crushing Equipment Available for Sale

Crushing Equipment For Sale - A New Opportunity for the Mining IndustryThe mining industry plays a vital role in our global economy by providing essential raw materials to various sectors such as construction, manufacturing, and infrastructure development. One of the critical components of the mining process is crushing equipment, which is used to break down large rocks and other hard materials into smaller, more manageable pieces. Without reliable and efficient crushing equipment, the mining industry would struggle to meet the demands of the market. With this in mind, the recent announcement of the availability of high-quality crushing equipment for sale is exciting news for mining companies around the world.As mining operations continue to expand and modernize, the demand for advanced crushing equipment has increased significantly. The need for more powerful and efficient machinery has prompted [Company Name], a leading manufacturer of mining equipment, to offer a wide range of crushing equipment for sale. With a focus on innovation and quality, [Company Name] has established itself as a trusted provider of mining solutions and has a strong reputation for delivering top-notch products to its customers.The crushing equipment that [Company Name] has available for sale includes jaw crushers, impact crushers, cone crushers, and other specialized machinery designed to handle the toughest materials encountered in mining operations. These machines are built to withstand heavy use and are capable of delivering high levels of productivity while minimizing downtime and maintenance costs. With advanced features such as hydraulic control systems, adjustable settings, and durable wearing parts, [Company Name]'s crushing equipment is designed to provide reliable performance in the most demanding environments.In addition to offering a range of standard crushing equipment, [Company Name] also provides custom solutions to meet the specific needs of its customers. Whether it's a unique material, a challenging operating environment, or a specific output requirement, [Company Name] has the expertise and resources to design and manufacture custom crushing equipment that meets the exact specifications of a mining operation. This level of customization ensures that customers can optimize their crushing processes and achieve the best possible results.In light of the current market conditions and the increasing demand for high-quality crushing equipment, the availability of [Company Name]'s products presents an excellent opportunity for mining companies to enhance their operations. By investing in cutting-edge crushing equipment, mining companies can improve their overall productivity, reduce operating costs, and ensure a more sustainable and efficient operation. The advanced technology and robust construction of [Company Name]'s crushing equipment are well-suited to tackle the challenges of modern mining and contribute to the success and profitability of mining operations.With a strong commitment to customer satisfaction and a dedication to delivering superior products, [Company Name] stands out as a reliable and reputable provider of crushing equipment. The company's extensive experience in the mining industry, combined with its technical expertise and innovative approach, positions it as a valuable partner for mining companies looking to upgrade their crushing capabilities. By choosing [Company Name]'s crushing equipment, customers can benefit from reliable performance, exceptional durability, and excellent after-sales support.As the mining industry continues to evolve, the availability of high-quality crushing equipment from a trusted manufacturer like [Company Name] presents an exciting opportunity for mining companies to improve their operations and achieve greater success. With a focus on innovation, quality, and customer satisfaction, [Company Name] is well-equipped to support the evolving needs of the mining industry and provide solutions that drive progress and growth. The availability of [Company Name]'s crushing equipment for sale marks a significant development in the mining industry and paves the way for enhanced efficiency, productivity, and value creation in mining operations.

Guide to Pipe Extrusion: Techniques and Benefits

Pipe Extrusion is a process used to create plastic pipes with consistent dimensions and high quality. The process involves melting plastic and then forming it into a continuous profile, which is then cooled and solidified. This method is commonly used in the manufacturing of various types of pipes, including water pipes, gas pipes, and drainage pipes.One company that has excelled in the field of pipe extrusion is {}. With years of experience and a strong commitment to quality, {} has become a leading manufacturer of plastic pipes. The company offers a wide range of pipe extrusion products, including PVC pipes, HDPE pipes, and PPR pipes, catering to the needs of various industries and applications.{} takes great pride in its state-of-the-art manufacturing facilities, which are equipped with the latest extrusion technology. The company has invested heavily in research and development to continually improve its production processes and product quality. This commitment to innovation has allowed {} to stay ahead of the competition and meet the ever-evolving demands of the market.One of the key factors that set {} apart from other manufacturers is its strict adherence to international standards and regulations. The company's pipes are manufactured in compliance with the highest industry standards, ensuring durability, reliability, and safety. This dedication to quality has earned {} a stellar reputation among its customers and business partners.In addition to its focus on quality, {} is also dedicated to sustainability and environmental responsibility. The company places a strong emphasis on using eco-friendly materials and production methods, minimizing its carbon footprint and contributing to a greener planet. This commitment to sustainability has not only benefited the environment but has also positioned {} as a socially responsible company in the eyes of its stakeholders.Furthermore, {} places a strong emphasis on customer satisfaction. The company's team of experts works closely with clients to understand their specific needs and provide tailored solutions. Whether it's customizing pipe dimensions, meeting specific performance requirements, or adhering to tight delivery schedules, {} always goes the extra mile to ensure customer satisfaction.The success and reputation of {} in the pipe extrusion industry can also be attributed to its strong focus on continuous improvement and excellence. The company has implemented rigorous quality control measures throughout its production processes, ensuring that every pipe that leaves its facilities meets the highest standards of quality and performance. This unwavering commitment to excellence has earned {} the trust and loyalty of its customers.Looking ahead, {} is poised to further strengthen its position in the pipe extrusion market. The company is constantly exploring new opportunities for growth and expansion, both domestically and internationally. With its solid foundation of experience, expertise, and commitment to quality, {} is well-equipped to take on new challenges and continue its success in the years to come.In conclusion, pipe extrusion is a critical process in the manufacturing of plastic pipes, and {} has established itself as a leader in this field. With a strong focus on quality, innovation, sustainability, customer satisfaction, and continuous improvement, {} has earned a stellar reputation and is well-positioned for further growth and success in the pipe extrusion industry.

High-Quality and Efficient Plastic Extruder Machine for Industrial Use

The global plastic extrusion industry is currently experiencing a surge in demand for high-quality and efficient extrusion machines. As a leading manufacturer in this industry, {Company Name} has been at the forefront of providing state-of-the-art Pe Extruder Machines to meet the growing needs of its clients worldwide.With a strong commitment to innovation and continuous improvement, {Company Name} has continuously invested in research and development to ensure that its Pe Extruder Machines are equipped with the latest technological advancements. This dedication to excellence has enabled the company to stay ahead of the competition and provide its customers with superior products that are both efficient and reliable.The Pe Extruder Machines offered by {Company Name} are designed to extrude polyethylene (PE) materials with precision and consistency. These machines are capable of processing a wide range of PE materials, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), to produce high-quality plastic products for various applications.One of the key features of {Company Name}'s Pe Extruder Machines is their versatility. These machines are designed to accommodate different types of PE materials and can be easily adjusted to meet specific production requirements. Whether it is the production of pipes, sheets, or films, {Company Name}'s Pe Extruder Machines are capable of delivering outstanding performance and efficiency.In addition to their versatility, {Company Name}'s Pe Extruder Machines are also known for their high production output. These machines are equipped with advanced extrusion technology that allows for faster processing speeds and higher production rates. This not only enhances the overall productivity of the manufacturing process but also enables clients to meet tight production deadlines and demands.Moreover, {Company Name} takes pride in the quality and durability of its Pe Extruder Machines. Each machine is built to the highest standards, using premium-grade materials and components to ensure long-lasting performance and reliability. This commitment to quality has earned {Company Name} a solid reputation for delivering machines that consistently exceed industry standards and customer expectations.Another noteworthy aspect of {Company Name}'s Pe Extruder Machines is their user-friendly design. These machines are intuitively designed to be easy to operate and maintain, making them ideal for both experienced and novice operators. Furthermore, {Company Name} provides comprehensive training and after-sales support to ensure that clients can maximize the capabilities of their Pe Extruder Machines.Furthermore, the commitment of {Company Name} to sustainability is reflected in the design and manufacturing of its Pe Extruder Machines. The company has implemented eco-friendly practices and technologies to minimize energy consumption and reduce environmental impact. This not only aligns with the industry's shift towards sustainable manufacturing but also enables clients to contribute to a greener and more sustainable future.{Company Name} has also established a global network of sales and service partners to ensure that its Pe Extruder Machines are readily available and fully supported worldwide. This extensive network enables the company to provide prompt assistance and technical support to clients in different regions, further enhancing their overall experience with {Company Name}'s products.Overall, {Company Name}'s Pe Extruder Machines epitomize the company's dedication to delivering top-of-the-line solutions that cater to the evolving needs of the plastic extrusion industry. With their advanced technology, versatility, high production output, quality construction, user-friendly design, and sustainability, these machines are setting new benchmarks for excellence in the industry.As the demand for high-quality Pe Extruder Machines continues to soar, {Company Name} remains committed to pushing the boundaries of innovation and setting new standards for the plastic extrusion industry. With its unwavering dedication to excellence and customer satisfaction, {Company Name} is poised to solidify its position as a global leader in the manufacturing of Pe Extruder Machines.

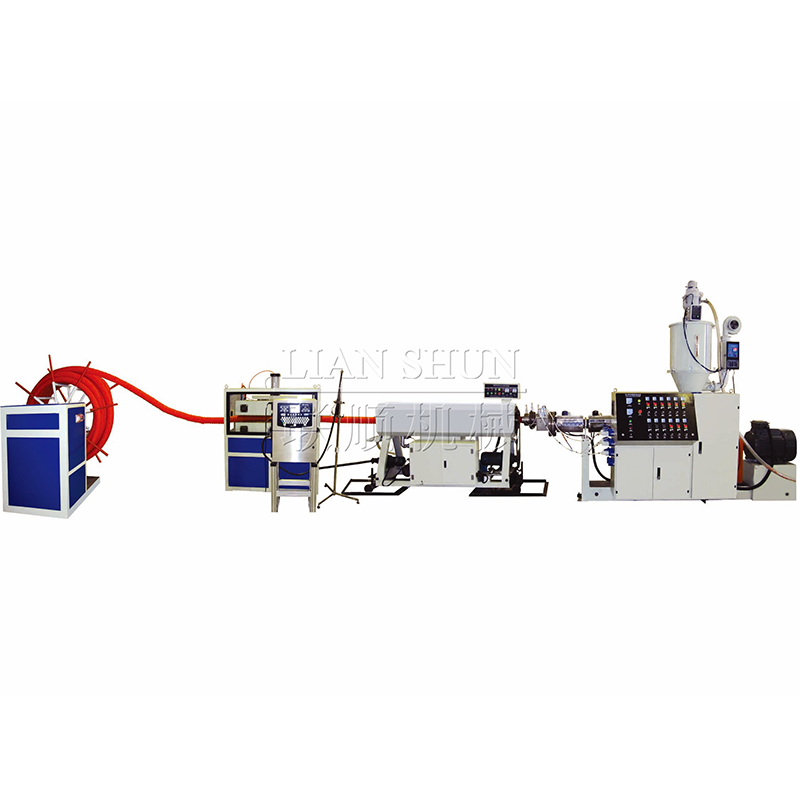

High-Quality Plastic Pipe Extrusion Line for Efficient Production

Plastic Pipe Extrusion Line is an essential equipment used in the manufacturing of plastic pipes for various applications such as water supply, drainage, and gas transmission. The demand for plastic pipes has been increasing steadily due to their lightweight, durability, and resistance to corrosion. To meet this growing demand, a leading manufacturer in the industry has introduced an innovative Plastic Pipe Extrusion Line, which is set to revolutionize the production process and improve efficiency.The Plastic Pipe Extrusion Line is equipped with advanced technology and features that make it a versatile and reliable solution for plastic pipe manufacturing. It is capable of processing a wide range of materials including PVC, PE, PP, and other thermoplastic materials to produce pipes of different sizes and specifications. The extrusion process is designed to ensure high precision and consistency, resulting in high-quality pipes that meet industry standards and requirements.One of the key highlights of the Plastic Pipe Extrusion Line is its high production capacity, which allows for continuous and uninterrupted manufacturing of pipes. This capability is crucial for meeting the demands of large-scale infrastructure projects and maintaining a steady supply of plastic pipes to the market. In addition, the line is designed for easy operation and maintenance, making it user-friendly and cost-effective for manufacturers.As a leading manufacturer in the plastic pipe industry, {} has a strong reputation for delivering high-quality and reliable equipment to its customers. The company has a proven track record of innovation and expertise in developing solutions that meet the evolving needs of the industry. The introduction of the new Plastic Pipe Extrusion Line is a testament to their commitment to driving progress and excellence in plastic pipe manufacturing.With a focus on quality, efficiency, and sustainability, {} is dedicated to providing cutting-edge solutions that benefit both manufacturers and end-users. The company's extensive experience and technical knowledge enable them to deliver tailored solutions that optimize production processes and drive business growth. The introduction of the new Plastic Pipe Extrusion Line is a significant milestone for the company and a demonstration of their leadership in the industry.In addition to the innovative technology integrated into the Plastic Pipe Extrusion Line, {} also offers comprehensive technical support and after-sales services to ensure the smooth operation of the equipment. This includes training, installation, maintenance, and troubleshooting assistance, providing customers with peace of mind and confidence in their investment. By partnering with a reputable manufacturer like {}, customers can expect a seamless experience from the initial setup to ongoing production.The introduction of the new Plastic Pipe Extrusion Line by {} marks a significant advancement in the plastic pipe manufacturing industry. With its advanced features, high production capacity, and reliable performance, the line is set to elevate the standards of plastic pipe production and contribute to the development of sustainable and efficient infrastructure. As the demand for plastic pipes continues to grow, manufacturers can rely on {} to provide them with the latest technology and solutions to stay ahead in the market.In conclusion, the new Plastic Pipe Extrusion Line introduced by {} represents a major leap forward in the plastic pipe manufacturing industry. With its advanced technology, high production capacity, and reliable performance, the line is poised to make a positive impact on the production of plastic pipes for various applications. By partnering with {}, manufacturers can benefit from a trusted and experienced ally that is committed to driving progress and excellence in the industry.

High-Quality Pipe Manufacturing Plant Producing Top-Notch Products

Pipe Manufacturing Plant Completes Expansion Project, Increases Production Capacity to Meet Growing Demand[City, State] - [Pipe Manufacturing Plant] has recently completed a major expansion project, marking a significant milestone for the company. The expansion includes the addition of new state-of-the-art equipment and facilities, which has significantly increased the plant's production capacity. This development comes at a time when the demand for high-quality pipes is on the rise, driven by growing infrastructure projects in the region.[Pipe Manufacturing Plant] is a leading manufacturer of a wide range of pipes for various applications, including industrial, commercial, and residential use. The company has built a solid reputation for delivering top-quality products, and the recent expansion is a testament to its commitment to meeting the needs of its customers.The newly expanded plant is now equipped with the latest technology, allowing for improved efficiency and productivity. This includes the installation of advanced pipe manufacturing machinery and equipment, as well as the addition of a larger warehouse and storage facility. With these upgrades, [Pipe Manufacturing Plant] has effectively doubled its production capacity, enabling the company to meet the growing demand for its products."We are thrilled to announce the completion of our expansion project, which represents a significant investment in our manufacturing capabilities," said [Name], CEO of [Pipe Manufacturing Plant]. "This expansion is a proactive response to the increasing market demand for our products, and it reinforces our commitment to providing our customers with the highest quality pipes in a timely manner."The expansion project has also created new job opportunities in the community, with the plant adding a significant number of positions to accommodate the increased production capacity. This has not only contributed to the local economy but has also provided employment opportunities for individuals with diverse skill sets.In addition to the expansion of its manufacturing facilities, [Pipe Manufacturing Plant] has also invested in enhancing its quality control processes to ensure that all products meet the highest industry standards. The company is dedicated to maintaining its position as a trusted supplier of pipes, and the recent improvements will further solidify its reputation for excellence in the market.As a socially responsible company, [Pipe Manufacturing Plant] is committed to sustainable and environmentally friendly manufacturing practices. The expansion project has been designed with this in mind, incorporating energy-efficient technologies and processes to minimize the plant's environmental footprint. This demonstrates the company's ongoing commitment to responsible and sustainable production methods.The completion of the expansion project has positioned [Pipe Manufacturing Plant] for continued growth and success in the industry. With its increased production capacity and enhanced capabilities, the company is well-equipped to meet the evolving needs of its customers and seize new opportunities in the market.Looking ahead, [Pipe Manufacturing Plant] is focused on leveraging its expanded facilities to explore new market segments and expand its product offerings. The company remains dedicated to innovation and customer satisfaction, and the recent expansion is a key step in its long-term growth strategy.Overall, the successful completion of the expansion project represents a major achievement for [Pipe Manufacturing Plant], and it underscores the company's commitment to delivering excellence in manufacturing and meeting the needs of its customers. As the demand for high-quality pipes continues to grow, [Pipe Manufacturing Plant] is well-positioned to play a pivotal role in shaping the future of the industry.

Durable Pulverizer Machine for Efficient Plastic Recycling

A leading manufacturer in the plastic processing industry, {company name}, has recently introduced a state-of-the-art pulverizer machine for plastic. This innovative machine is designed to meet the growing demand for efficient and high-quality plastic processing equipment in the market.The new pulverizer machine is equipped with advanced technologies and cutting-edge features that set it apart from traditional models. It is specifically engineered to handle a wide range of plastic materials, including PVC, PE, and PET, with precision and reliability. The machine is capable of pulverizing plastic waste into fine particles, making it easier to recycle and reuse for various applications.One of the key highlights of the pulverizer machine is its high-speed grinding capacity, which ensures consistent and uniform particle size reduction. This feature is particularly beneficial for plastic manufacturers and recycling facilities that require precise control over the final product's quality. Additionally, the machine's durable construction and low maintenance requirements make it a cost-effective investment for businesses looking to streamline their plastic processing operations.{company name} has a strong reputation for delivering industry-leading solutions to the plastic processing sector. With decades of experience and expertise, the company has continually set new standards for innovation and performance in the industry. The introduction of the new pulverizer machine further solidifies {company name}'s commitment to providing cutting-edge equipment that meets the evolving needs of its customers."We are thrilled to launch our latest pulverizer machine for plastic, which represents a significant advancement in the field of plastic processing technology," said a spokesperson for {company name}. "This machine is the result of our ongoing efforts to develop solutions that enable our customers to achieve greater efficiency, productivity, and sustainability in their operations."In addition to offering best-in-class equipment, {company name} also provides comprehensive technical support and after-sales services to ensure that its customers can maximize the performance and longevity of their investment. The company's team of skilled engineers and technicians are readily available to assist with installation, training, maintenance, and troubleshooting, further contributing to the overall value proposition of the new pulverizer machine.The launch of the new pulverizer machine for plastic underscores {company name}'s proactive approach to addressing the growing environmental and economic challenges facing the plastic industry. With a focus on promoting waste reduction, energy efficiency, and resource conservation, the company is dedicated to empowering its customers with sustainable solutions that drive positive change.As the plastic industry continues to evolve, {company name} remains at the forefront of innovation, delivering cutting-edge solutions that enable its customers to stay ahead of the curve. The new pulverizer machine for plastic exemplifies the company's unwavering commitment to driving progress and shaping the future of plastic processing.With its exceptional performance capabilities, advanced features, and reliable support services, the new pulverizer machine from {company name} is poised to set a new standard for excellence in plastic processing. As businesses seek to optimize their operations and reduce their environmental footprint, this innovative machine is perfectly positioned to meet their needs and deliver tangible value for years to come.

High-Quality and Efficient Floor Making Machine for Your Business

Floor Making Machine revolutionizes the flooring industry with innovative technologyThe flooring industry has been revolutionized with the introduction of the latest Floor Making Machine by a leading company in the sector. This advanced machine is designed to streamline the process of floor production, ensuring high quality and efficiency.The Floor Making Machine is equipped with state-of-the-art technology, allowing for precise and accurate production of various types of flooring. Whether it's vinyl, laminate, or hardwood, this machine is able to handle a wide range of materials and produce top-notch flooring products.One of the key features of the Floor Making Machine is its flexibility and versatility. It can be easily adjusted to accommodate different specifications and requirements, making it suitable for both small-scale and large-scale production. This versatility is a major advantage for flooring manufacturers, as it allows them to meet the diverse needs of their customers with ease.In addition to its flexibility, the Floor Making Machine also boasts a high level of automation, reducing the need for manual labor and increasing overall efficiency. This automation not only speeds up the production process, but also ensures consistency and precision in the finished products. As a result, flooring manufacturers can enjoy increased productivity and reduced production costs, ultimately leading to higher profitability.Furthermore, the Floor Making Machine is designed with user-friendly interfaces and intuitive controls, making it easy for operators to learn and operate. This user-friendly design is a significant advantage for flooring companies, as it minimizes the need for extensive training and ensures smooth operation of the machine.The company behind this innovative Floor Making Machine is a renowned leader in the flooring industry, with a long-standing reputation for delivering cutting-edge solutions. With a strong focus on research and development, the company has continuously strived to push the boundaries of innovation in the flooring sector, and the latest Floor Making Machine is a testament to their commitment to excellence.In addition to its technological prowess, the company also prides itself on its dedication to sustainability and environmental responsibility. The Floor Making Machine is designed to minimize waste and reduce energy consumption, aligning with the company's eco-friendly ethos. This commitment to sustainability not only benefits the environment, but also resonates with customers who prioritize ethical and responsible business practices.Moreover, the company provides comprehensive support and after-sales services for the Floor Making Machine, ensuring that customers receive the necessary assistance and guidance to maximize the machine's potential. This commitment to customer satisfaction and support further solidifies the company's position as a trusted partner for flooring manufacturers around the world.Overall, the introduction of the Floor Making Machine by this leading company marks a significant milestone in the flooring industry. With its advanced technology, flexibility, and user-friendly design, this machine has the potential to revolutionize the way flooring is produced, setting new standards for quality, efficiency, and sustainability.As the demand for high-quality flooring continues to grow, the Floor Making Machine offers a game-changing solution for flooring manufacturers, empowering them to meet the evolving needs of the market with confidence and competence. It is indeed an exciting time for the flooring industry, as this innovative machine paves the way for a new era of innovation and progress.

Efficient Plastic Shredder Machine for Recycling Plant

Plastic Recycling Plant Introduces New Shredder Machine to Enhance EfficiencyIn a continuous effort to promote environmental sustainability, [Company Name], a leading plastic recycling plant, has recently invested in a state-of-the-art plastic shredder machine. This new addition to their recycling infrastructure is set to significantly enhance the efficiency of their operations and further solidify their commitment to sustainable practices.The [Company Name] has long been dedicated to mitigating the detrimental effects of plastic waste on the environment. With the increasing concern over plastic pollution, the company has made it their mission to divert plastic materials from landfills and instead, recycle and repurpose them into valuable products. This aligns with their ethos of promoting a circular economy and reducing the reliance on virgin materials.The new plastic shredder machine will play a crucial role in achieving these objectives. By investing in cutting-edge technology, [Company Name] aims to streamline the recycling process and increase the capacity to handle larger volumes of plastic waste. This will allow them to process material more efficiently and meet the growing demand for recycled plastic products.The shredder machine boasts advanced features that set it apart from traditional equipment. Its high-speed blades and robust construction enable it to shred various types of plastic, including rigid plastics such as PET bottles, HDPE containers, and PVC pipes, as well as flexible plastics like plastic bags and packaging films. This versatility ensures that a wide range of plastic materials can be effectively processed, contributing to the plant's overall efficiency.Furthermore, the shredder is equipped with advanced safety mechanisms and control systems to ensure smooth and secure operation. This not only safeguards the well-being of the plant's workforce but also minimizes downtime and maintenance, leading to continuous and uninterrupted recycling processes.With the installation of the new shredder machine, [Company Name] anticipates a substantial increase in their recycling output, which will in turn bolster their supply of high-quality recycled plastic materials. This will enable them to cater to the needs of industries seeking sustainable alternatives to virgin plastics, such as packaging, construction, and manufacturing.In addition to its operational benefits, the shredder machine aligns with [Company Name]'s environmental objectives. By effectively shredding and processing plastic waste, the plant aims to minimize the reliance on raw materials derived from fossil fuels, thus reducing the carbon footprint associated with plastic production. Ultimately, this contributes to the conservation of natural resources and the reduction of greenhouse gas emissions.As part of their ongoing commitment to sustainability, [Company Name] is also dedicated to investing in research and development to further improve their recycling processes. They are exploring the integration of innovative technologies, such as sorting and washing systems, to enhance the quality and purity of their recycled plastic materials. This relentless pursuit of excellence underscores their determination to be at the forefront of sustainable initiatives within the recycling industry.The introduction of the new plastic shredder machine signifies a significant milestone for [Company Name] and underscores their unwavering dedication to environmental stewardship. By embracing cutting-edge technology and implementing best practices, the plant is primed to elevate its position as a leading force in the field of plastic recycling. Their efforts not only contribute to a cleaner and healthier environment but also pave the way for a more sustainable future for generations to come.

High Quality Extruder Prices and Offers in the Market

Extruder Prices on the Rise in the Manufacturing IndustryThe manufacturing industry is currently experiencing a significant increase in the prices of extruders, with reports indicating that the cost of these vital machines has surged in recent weeks. The rise in extruder prices has been attributed to various factors, including increased demand for these machines, supply chain disruptions, and rising raw material costs. As a result, companies within the manufacturing sector are facing greater financial pressure and are being forced to reassess their procurement strategies in light of these escalating costs.The surge in extruder prices has been a cause for concern for many companies within the manufacturing industry. Extruders play a crucial role in the production process, as they are used to create a wide range of products across various sectors, including plastics, food, pharmaceuticals, and construction materials. As such, any significant increase in the cost of these machines can have a direct impact on the overall operational costs and profitability of manufacturing companies.One of the primary reasons for the rise in extruder prices is the unprecedented increase in demand for these machines. The manufacturing industry has seen a surge in production activities in recent months, driven by a rebound in global economic activity and strong consumer demand for goods. This increase in production has led to a greater need for extruders, as companies seek to ramp up their manufacturing capabilities to meet the growing demand for their products.In addition to surging demand, supply chain disruptions have also played a significant role in driving up extruder prices. The global supply chain has been heavily impacted by the COVID-19 pandemic, with disruptions in logistics, transportation, and raw material supply causing delays and shortages across various industries. These disruptions have made it increasingly challenging for manufacturers to secure the necessary components and materials for their production processes, leading to higher costs and longer lead times for extruders.Furthermore, rising raw material costs have also contributed to the increase in extruder prices. The manufacturing industry relies on a variety of raw materials, such as metals, plastics, and electronic components, to produce its products. The surge in demand for these materials, coupled with supply chain disruptions and logistical challenges, has led to a sharp increase in their prices, ultimately driving up the overall cost of extruders.In response to the rising extruder prices, many manufacturing companies have been forced to reevaluate their procurement strategies and find ways to mitigate the impact of these escalating costs. Some companies have opted to explore alternative suppliers and vendors in an effort to secure better pricing and more reliable delivery schedules. Others have sought to renegotiate existing contracts and agreements with their suppliers to ensure more favorable terms in light of the current market conditions.Additionally, some companies are considering investing in advanced extruder technologies that offer greater operational efficiency and cost savings in the long run. By upgrading to more efficient and productive extruder machines, manufacturers can potentially offset the impact of rising prices through improved productivity and reduced operational costs.It is worth noting that despite the challenges posed by the current surge in extruder prices, the manufacturing industry remains resilient and adaptable. Companies continue to seek innovative solutions and strategies to navigate the current market dynamics and ensure their long-term sustainability and growth.In conclusion, the manufacturing industry is grappling with a significant increase in extruder prices, driven by factors such as surging demand, supply chain disruptions, and rising raw material costs. As companies seek to mitigate the impact of these rising prices, they are exploring various strategies, including alternative sourcing, renegotiating contracts, and investing in advanced technologies. Despite these challenges, the manufacturing industry remains resilient and committed to overcoming the current market pressures in pursuit of sustainable growth and success.