Top Pulverizer and Grinder Options for Effective Material Processing

By:Admin

Specializing in the production of pulverizers and grinders, the company has gained a strong reputation for its unwavering dedication to quality and customer satisfaction. Its state-of-the-art manufacturing facilities, equipped with the latest technology and machinery, enable it to produce cutting-edge equipment that meets the highest industry standards.

The company's pulverizers and grinders are widely utilized across various industries, including pharmaceuticals, chemicals, food processing, and more. Known for their reliability, efficiency, and durability, these machines have become the go-to choice for businesses seeking to enhance their production processes and maximize output.

One of the key factors that sets Pulverizer And Grinder apart from its competitors is its relentless pursuit of innovation. The company continuously invests in research and development to stay ahead of the curve and introduce advanced features and capabilities in its products. This commitment to innovation has allowed it to stay abreast of evolving industry trends and consistently meet the changing needs of its customers.

Moreover, Pulverizer And Grinder takes pride in its team of highly skilled engineers and technicians who possess in-depth knowledge and expertise in the field of industrial machinery. Their wealth of experience enables them to design and manufacture pulverizers and grinders that not only meet but exceed the expectations of clients, setting new benchmarks in terms of performance and reliability.

In addition to its impressive product range, the company also places a strong emphasis on providing excellent customer service. With a focus on building long-term partnerships with its clients, Pulverizer And Grinder offers comprehensive support and maintenance services to ensure that its equipment continues to deliver optimal performance throughout its lifespan. This commitment to customer satisfaction has helped the company forge strong relationships with a loyal and growing customer base.

As a testament to its dedication to quality, Pulverizer And Grinder adheres to stringent quality control measures at every stage of the manufacturing process. From sourcing the finest raw materials to conducting rigorous quality checks on the finished products, the company ensures that only the best-in-class equipment leaves its facilities. This unwavering commitment to quality has earned Pulverizer And Grinder the trust and confidence of its clients, further solidifying its position as a respected industry leader.

Looking ahead, Pulverizer And Grinder is poised to continue its journey of growth and success, driven by its core values of excellence, innovation, and customer satisfaction. With a steadfast focus on staying ahead of the competition and delivering unparalleled value to its clients, the company is well-positioned to further expand its presence in the global market.

In conclusion, Pulverizer And Grinder stands out as a company that exemplifies the highest standards of quality, innovation, and customer service in the field of industrial machinery manufacturing. With a strong track record of success and a vision for the future, the company is set to achieve even greater milestones and solidify its position as a powerhouse in the industry.

Company News & Blog

Efficient PE Film Pelletizing: A Comprehensive Guide

Pe Film Pelletizing Market: Growing Demand for Sustainable Packaging SolutionsThe global market for PE film pelletizing is witnessing significant growth, driven by the increasing demand for sustainable packaging solutions across various industries. Polyethylene (PE) film is widely used for packaging applications due to its excellent properties such as flexibility, durability, and moisture resistance. However, the disposal of PE film waste has been a major environmental concern, leading to the adoption of PE film pelletizing technology to recycle and reuse the material.The rise in environmental awareness and the implementation of stringent regulations regarding plastic waste management have led to the surge in demand for PE film pelletizing solutions. Companies across different industries are increasingly focusing on sustainable packaging practices to minimize their carbon footprint and contribute to environmental conservation. As a result, the market for PE film pelletizing is experiencing steady growth, with manufacturers offering advanced technologies and solutions to cater to the growing demand.One of the leading players in the market, [Company Name], is at the forefront of providing innovative PE film pelletizing solutions to meet the evolving needs of the packaging industry. The company specializes in developing state-of-the-art pelletizing equipment and systems that enable efficient recycling and processing of PE film waste. With a strong focus on sustainability, [Company Name] is dedicated to offering reliable and cost-effective solutions to its customers, helping them achieve their environmental goals while enhancing operational efficiency.[Company Name] has a comprehensive range of PE film pelletizing equipment, including extruders, pelletizers, and related components, designed to deliver high-quality recycled pellets suitable for various applications. The company's expertise in designing and manufacturing pelletizing systems has earned it a solid reputation in the market, with a strong customer base spanning across different industries such as packaging, automotive, construction, and agriculture. The advanced technologies offered by [Company Name] enable companies to transform PE film waste into valuable resources, contributing to the circular economy and reducing the environmental impact of plastic packaging.In addition to providing cutting-edge equipment, [Company Name] also offers comprehensive technical support and after-sales services to ensure the smooth operation and maintenance of its pelletizing systems. The company's team of experienced engineers and technicians are dedicated to assisting customers with installation, commissioning, and troubleshooting, further enhancing the overall customer experience. With a commitment to innovation and customer satisfaction, [Company Name] continues to lead the way in the PE film pelletizing market, driving sustainable solutions for the packaging industry.The market for PE film pelletizing is projected to witness substantial growth in the coming years, as the demand for sustainable packaging solutions continues to rise. The adoption of advanced pelletizing technologies and the increasing emphasis on recycling and reusing plastic waste will further fuel the market expansion. Leading players like [Company Name] are poised to capitalize on this trend by offering efficient and reliable PE film pelletizing solutions, catering to the evolving needs of customers across the globe.In conclusion, the PE film pelletizing market is experiencing a significant upsurge, driven by the growing demand for sustainable packaging solutions and the increasing focus on plastic waste management. Companies like [Company Name] are playing a pivotal role in providing advanced PE film pelletizing technologies to enable the recycling and reprocessing of PE film waste. As the market continues to evolve, [Company Name] remains committed to delivering innovative and sustainable solutions, contributing to the development of a more environmentally friendly packaging industry.Overall, the outlook for the PE film pelletizing market looks promising, with ample opportunities for growth and advancement in the years to come. With the industry's increasing focus on sustainability and circular economy principles, the demand for PE film pelletizing solutions is expected to soar, creating new avenues for innovation and development in the packaging sector. As a result, companies like [Company Name] are well-positioned to capitalize on this trend and drive the market forward with their cutting-edge technologies and unwavering commitment to environmental stewardship.

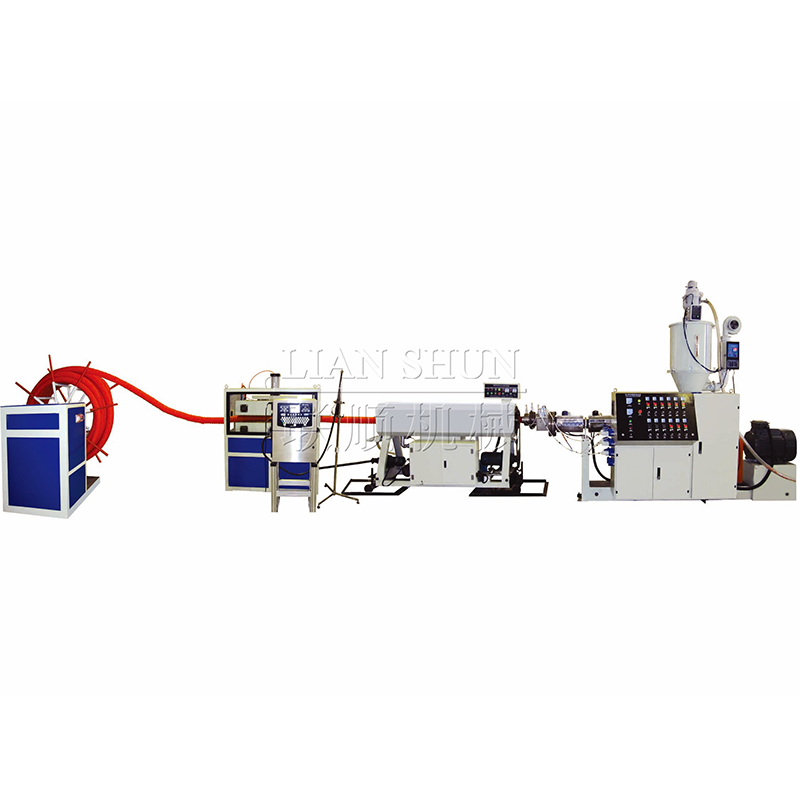

Tube PVC fabrication: What you need to know

Machine Fabrication Tube Pvc (MFTP) is a leading company in the field of manufacturing PVC tubes through a state-of-the-art fabrication process. With a commitment to quality and innovation, MFTP has established itself as a trusted provider of PVC tubes for various industries.MFTP’s fabrication process is highly advanced, utilizing cutting-edge machinery and technology to ensure the production of high-quality PVC tubes. The company’s production facility is equipped with the latest extrusion machines, which are capable of producing a wide range of PVC tube sizes and specifications. This allows MFTP to cater to the diverse needs of its customers, offering customized solutions for specific applications.In addition to its cutting-edge machinery, MFTP also takes pride in its team of qualified and experienced professionals. The company’s dedicated workforce is committed to upholding the highest standards of quality and consistency in production. From design and engineering to manufacturing and quality control, MFTP’s team works tirelessly to deliver excellence in every aspect of the fabrication process.MFTP’s PVC tubes are widely used across various industries, including construction, plumbing, electrical, and agriculture. The company’s PVC tubes are known for their durability, flexibility, and resistance to corrosion, making them ideal for a wide range of applications. Whether it’s for water distribution, sewage systems, cable protection, or irrigation, MFTP provides the perfect PVC tube solutions for different needs.Furthermore, MFTP is committed to sustainability and environmental responsibility in its production processes. The company adheres to strict environmental regulations and implements eco-friendly practices in its manufacturing operations. This includes recycling and waste management initiatives, as well as the use of raw materials that are free from harmful substances, ensuring that MFTP’s PVC tubes are safe for both people and the environment.One of the key factors that sets MFTP apart in the industry is its dedication to customer satisfaction. The company places a strong emphasis on understanding the unique requirements of its clients and providing them with tailored solutions that meet their specific needs. With a customer-centric approach, MFTP has built long-lasting relationships with clients and has earned a reputation for reliability and trustworthiness.In addition to its commitment to quality and customer satisfaction, MFTP also places a high value on continuous innovation and improvement. The company invests in research and development to stay ahead of the curve in terms of technological advancements and product enhancements. This allows MFTP to offer cutting-edge PVC tube solutions that are at the forefront of industry standards.As MFTP continues to grow and expand its presence in the market, the company remains dedicated to upholding its core values of quality, innovation, sustainability, and customer satisfaction. With a strong focus on excellence and a forward-thinking approach, MFTP is poised to continue its success as a leader in PVC tube fabrication.In conclusion, Machine Fabrication Tube Pvc (MFTP) is a reputable company that stands out as a leading provider of high-quality PVC tubes. With its state-of-the-art fabrication process, commitment to sustainability, customer-centric approach, and emphasis on innovation, MFTP has solidified its position as a trusted partner for industries that rely on top-notch PVC tube solutions. Looking ahead, MFTP is set to maintain its success and continue delivering excellence in the field of PVC tube fabrication.

Powerful Pipe Crusher for Efficient Waste Management

Pipe Crusher: A Revolutionary Solution for Waste ManagementIn today's world, waste management has become a growing concern for communities and industries alike. With a focus on sustainability and environmental safety, companies are constantly seeking innovative solutions to effectively manage their waste. This is where the Pipe Crusher comes into play - a revolutionary machine that offers a sustainable and efficient solution for waste management.{Company Name} is a leading provider of cutting-edge technology and machinery for various industries. With a focus on environmental sustainability and waste management, {Company Name} has developed the Pipe Crusher to address the challenges faced by industries in dealing with waste materials. The company has a long-standing reputation for delivering reliable and high-quality solutions, making them a trusted partner for businesses across different sectors.The Pipe Crusher is a state-of-the-art machine designed to effectively crush and reduce the volume of waste materials such as pipes, tubes, and other similar items. It is equipped with a powerful motor and cutting blades that can easily process large quantities of waste, significantly reducing the volume and making it easier to handle and transport. This innovative machine is designed to streamline waste management processes, saving time and resources for industries dealing with large volumes of waste materials.One of the key features of the Pipe Crusher is its versatility. The machine is designed to accommodate a wide range of pipe sizes and materials, making it a flexible solution for different industries. Whether it is plastic, metal, or other materials, the Pipe Crusher can effectively process and reduce the volume of waste, making it an ideal solution for companies dealing with diverse types of waste materials.The environmental impact of the Pipe Crusher cannot be overstated. By reducing the volume of waste materials, the machine helps companies minimize their carbon footprint and contribute to a more sustainable approach to waste management. With a focus on efficiency and sustainability, the Pipe Crusher is a game-changer for industries looking to improve their waste management processes and minimize their environmental impact.{Company Name} takes pride in offering a comprehensive solution for waste management. In addition to the Pipe Crusher, the company provides expert guidance and support to help businesses integrate the machine into their waste management processes seamlessly. With a team of experienced professionals, {Company Name} delivers top-notch customer service, ensuring that businesses receive the necessary support and assistance to maximize the benefits of the Pipe Crusher.As industries continue to prioritize sustainability and environmental responsibility, the Pipe Crusher has emerged as a valuable asset for businesses seeking to improve their waste management practices. With its ability to efficiently process and reduce the volume of waste materials, the machine offers a cost-effective and sustainable solution for industries across various sectors. The Pipe Crusher is a testament to {Company Name}’s commitment to innovation and sustainability, providing businesses with a reliable and efficient tool for waste management.In conclusion, the Pipe Crusher is a revolutionary solution for waste management, offering a sustainable and efficient approach to handling waste materials. {Company Name} continues to be a leading provider of innovative technology and machinery, delivering reliable solutions for industries seeking to improve their waste management practices. With its versatility, environmental impact, and commitment to customer support, the Pipe Crusher is a game-changer for industries looking to streamline their waste management processes and minimize their environmental footprint.

Ultimate Guide to Co Extruders: Everything You Need to Know

Co Extruder Revolutionizes the Plastic Extrusion IndustryFor over two decades, {} has been a leading manufacturer of innovative machinery and equipment for the plastic extrusion industry. Their commitment to excellence and customer satisfaction has made them a trusted name in the industry. Recently, the company has introduced a game-changing product that is set to revolutionize the way plastic extrusion is done - the Co Extruder.The Co Extruder is a cutting-edge machine that offers a range of benefits and features designed to improve productivity, efficiency, and quality in plastic extrusion processes. With its advanced technology and user-friendly interface, the Co Extruder is set to become an essential tool for manufacturers in the industry.One of the key features of the Co Extruder is its ability to perform co-extrusion, a process where two or more materials are extruded through a single die to form a single, multi-layered product. This capability opens up a world of possibilities for manufacturers, allowing them to create products with enhanced properties and performance. With the Co Extruder, manufacturers can easily customize the thickness and composition of each layer, resulting in products with superior strength, durability, and other desired characteristics.Additionally, the Co Extruder is equipped with state-of-the-art control systems that allow for precise monitoring and adjustment of various parameters such as temperature, pressure, and speed. This level of control helps to ensure consistent product quality and minimizes the risk of defects or inconsistencies in the final product. The machine is also designed to be highly efficient, maximizing productivity while minimizing waste and energy consumption.Another highlight of the Co Extruder is its versatility and adaptability to a wide range of applications. Whether it's for producing pipes, tubing, profiles, or sheeting, the Co Extruder can handle a variety of materials including PVC, PE, PP, and more. Its modular design also allows for easy customization and upgrades to meet specific production requirements."We are thrilled to introduce the Co Extruder to the market," said a spokesperson for {}. "We believe that this machine represents a significant advancement in plastic extrusion technology and will bring about positive changes in the industry. Our team has worked tirelessly to develop a product that meets the evolving needs of our customers, and we are confident that the Co Extruder will exceed their expectations."As part of their commitment to customer satisfaction, {} provides comprehensive support and maintenance services for the Co Extruder. Their team of skilled technicians is available to assist with installation, training, troubleshooting, and ongoing maintenance to ensure the optimal performance and longevity of the machine.The introduction of the Co Extruder underscores {}'s dedication to innovation and excellence in the plastic extrusion industry. With its cutting-edge technology, user-friendly design, and versatile capabilities, the Co Extruder is poised to become a game-changer for manufacturers looking to elevate their production capabilities and stay ahead of the competition. As the industry continues to evolve, the Co Extruder is set to play a pivotal role in shaping the future of plastic extrusion.

High Quality Extruder Prices and Offers in the Market

Extruder Prices on the Rise in the Manufacturing IndustryThe manufacturing industry is currently experiencing a significant increase in the prices of extruders, with reports indicating that the cost of these vital machines has surged in recent weeks. The rise in extruder prices has been attributed to various factors, including increased demand for these machines, supply chain disruptions, and rising raw material costs. As a result, companies within the manufacturing sector are facing greater financial pressure and are being forced to reassess their procurement strategies in light of these escalating costs.The surge in extruder prices has been a cause for concern for many companies within the manufacturing industry. Extruders play a crucial role in the production process, as they are used to create a wide range of products across various sectors, including plastics, food, pharmaceuticals, and construction materials. As such, any significant increase in the cost of these machines can have a direct impact on the overall operational costs and profitability of manufacturing companies.One of the primary reasons for the rise in extruder prices is the unprecedented increase in demand for these machines. The manufacturing industry has seen a surge in production activities in recent months, driven by a rebound in global economic activity and strong consumer demand for goods. This increase in production has led to a greater need for extruders, as companies seek to ramp up their manufacturing capabilities to meet the growing demand for their products.In addition to surging demand, supply chain disruptions have also played a significant role in driving up extruder prices. The global supply chain has been heavily impacted by the COVID-19 pandemic, with disruptions in logistics, transportation, and raw material supply causing delays and shortages across various industries. These disruptions have made it increasingly challenging for manufacturers to secure the necessary components and materials for their production processes, leading to higher costs and longer lead times for extruders.Furthermore, rising raw material costs have also contributed to the increase in extruder prices. The manufacturing industry relies on a variety of raw materials, such as metals, plastics, and electronic components, to produce its products. The surge in demand for these materials, coupled with supply chain disruptions and logistical challenges, has led to a sharp increase in their prices, ultimately driving up the overall cost of extruders.In response to the rising extruder prices, many manufacturing companies have been forced to reevaluate their procurement strategies and find ways to mitigate the impact of these escalating costs. Some companies have opted to explore alternative suppliers and vendors in an effort to secure better pricing and more reliable delivery schedules. Others have sought to renegotiate existing contracts and agreements with their suppliers to ensure more favorable terms in light of the current market conditions.Additionally, some companies are considering investing in advanced extruder technologies that offer greater operational efficiency and cost savings in the long run. By upgrading to more efficient and productive extruder machines, manufacturers can potentially offset the impact of rising prices through improved productivity and reduced operational costs.It is worth noting that despite the challenges posed by the current surge in extruder prices, the manufacturing industry remains resilient and adaptable. Companies continue to seek innovative solutions and strategies to navigate the current market dynamics and ensure their long-term sustainability and growth.In conclusion, the manufacturing industry is grappling with a significant increase in extruder prices, driven by factors such as surging demand, supply chain disruptions, and rising raw material costs. As companies seek to mitigate the impact of these rising prices, they are exploring various strategies, including alternative sourcing, renegotiating contracts, and investing in advanced technologies. Despite these challenges, the manufacturing industry remains resilient and committed to overcoming the current market pressures in pursuit of sustainable growth and success.

High-efficiency Single Screw Plastic Extruder for Plastic Manufacturing

The Single Screw Plastic Extruder is a cutting-edge machine that has revolutionized the plastic manufacturing industry. With its advanced technology and efficient production capabilities, it has become an essential tool for companies looking to streamline their plastic extrusion processes.This innovative extruder is designed to melt and reshape plastic materials into various forms, such as pipes, tubes, and sheets. It is equipped with a single screw mechanism that effectively heats and compresses the plastic, resulting in high-quality and uniform output. The extruder is also capable of handling a wide range of plastic materials, including polyethylene, polypropylene, PVC, and more, making it a versatile and adaptable solution for manufacturers.One of the key features of the Single Screw Plastic Extruder is its precision and consistency in production. The machine is equipped with state-of-the-art control systems that ensure accurate temperature regulation and material flow, resulting in precise shaping and sizing of the extruded products. This level of control and precision is crucial for meeting strict quality standards and dimensional requirements, making the extruder an ideal choice for companies with high-performance expectations.In addition to its exceptional production capabilities, the extruder also offers significant operational efficiency. Its streamlined design and user-friendly interface make it easy to operate, requiring minimal supervision and maintenance. This not only reduces labor costs but also maximizes productivity, allowing manufacturers to meet demand and deadlines more effectively. Furthermore, the extruder is built with durability and reliability in mind, ensuring long-term performance and minimal downtime for continuous production.It is also worth mentioning that the company behind the Single Screw Plastic Extruder, [Company Name], has a long-standing reputation for delivering high-quality and innovative machinery for the plastic industry. With a team of experienced engineers and industry experts, the company is committed to developing advanced solutions that meet the evolving needs of manufacturers. This commitment to excellence is reflected in the design and performance of the extruder, solidifying [Company Name]'s position as a trusted provider of plastic extrusion technology.The company's dedication to customer satisfaction is also evident in its comprehensive support and service offerings. From installation to troubleshooting, [Company Name] provides extensive assistance to ensure that the extruder operates at its full potential. This level of support is invaluable to manufacturers, as it minimizes disruptions and optimizes the overall efficiency of their production processes.Overall, the Single Screw Plastic Extruder is a game-changing solution for manufacturers seeking to enhance their plastic extrusion capabilities. With its advanced technology, precision production, and operational efficiency, it has set a new standard for plastic extrusion machinery. Coupled with [Company Name]'s expertise and support, the extruder is poised to drive innovation and excellence in the plastic manufacturing industry for years to come.

Innovative Plastic Densifier Machine for Efficient Plastic Recycling

In today's world, the issue of plastic waste has become a growing concern. With an increasing amount of plastic being produced and discarded daily, it is essential for businesses and industries to find sustainable solutions for managing and recycling plastic waste. One company that is leading the way in this effort is {}.{} is a renowned company that specializes in providing innovative solutions for recycling and waste management. With a focus on environmental sustainability and corporate responsibility, they have continuously strived to develop cutting-edge technologies that help businesses and industries reduce their environmental footprint. One of their most recent innovations is the introduction of their Plastic Densifier Machine, which is set to revolutionize the way plastic waste is processed and recycled.The Plastic Densifier Machine developed by {} is a state-of-the-art piece of equipment that is designed to compact and densify plastic waste, making it easier and more cost-effective to transport and recycle. By using a combination of heat and pressure, the machine is able to reduce the volume of plastic waste by up to 90%, significantly reducing the amount of space required for storage and transportation. This not only helps businesses and industries save on storage and transportation costs but also minimizes the environmental impact of plastic waste by reducing the amount of space it occupies in landfills.One of the key features of the Plastic Densifier Machine is its versatility and efficiency. It is capable of processing a wide range of plastic materials, including PET, HDPE, LDPE, and many others, making it a valuable asset for businesses and industries that deal with different types of plastic waste. Furthermore, the machine is designed to operate with minimal energy consumption, making it a cost-effective and sustainable solution for plastic waste management.In addition to its technical capabilities, the Plastic Densifier Machine is also backed by excellent customer support and service from {}. The company provides comprehensive training and support to businesses and industries that invest in their technology, ensuring that they are able to maximize the benefits of the machine and operate it efficiently. This dedication to customer satisfaction and support sets {} apart as a leader in the field of recycling and waste management technology.The introduction of the Plastic Densifier Machine marks a significant step forward in the efforts to tackle the global issue of plastic waste. By providing businesses and industries with a sustainable and efficient solution for managing and recycling plastic waste, {} is helping to drive positive change and promote environmental sustainability. As the demand for responsible waste management solutions continues to grow, the Plastic Densifier Machine is set to play a crucial role in shaping the future of plastic waste management.In conclusion, the Plastic Densifier Machine developed by {} represents a breakthrough in the field of plastic waste management. With its innovative technology, efficiency, and excellent customer support, it is set to make a significant impact on the way businesses and industries approach the issue of plastic waste. As a company that is committed to environmental sustainability and corporate responsibility, {} continues to lead the way in providing sustainable solutions for recycling and waste management, and the introduction of the Plastic Densifier Machine is a testament to their dedication to driving positive change.

Durable and Efficient Plastic Crusher Machines for Waste Management

Plastic Crusher Machine Revolutionizing Waste ManagementIn the midst of the global waste management crisis, the need for efficient and eco-friendly solutions has never been more pressing. Fortunately, one company has been at the forefront of developing innovative waste management technologies to combat this issue. Based in {company location}, {Company Name} has been leading the way in providing cutting-edge machinery for recycling and waste management, with their latest breakthrough being the Plastic Crusher Machine.The Plastic Crusher Machine is a revolutionary tool that is set to change the landscape of plastic waste management. With its advanced technology and user-friendly design, this machine has been designed to effectively crush and recycle plastic waste, significantly reducing the environmental impact of plastic pollution. This is a major step forward in the fight against plastic pollution, as it provides an efficient and sustainable solution for managing plastic waste.The Plastic Crusher Machine is equipped with a powerful motor and high-quality blades that are designed to efficiently crush and shred various types of plastic materials. Whether it is plastic bottles, containers, or packaging materials, this machine is capable of processing a wide range of plastic waste, making it an essential tool for recycling facilities, waste management companies, and businesses looking to reduce their environmental footprint.In addition to its powerful performance, the Plastic Crusher Machine is also designed with user safety and convenience in mind. Featuring a robust and durable construction, as well as advanced safety features, this machine ensures that operators can use it with confidence and peace of mind. Its user-friendly controls and easy maintenance make it a versatile and practical solution for businesses and facilities of all sizes.{Company Name} is known for its commitment to developing sustainable and environmentally friendly solutions for waste management. With a focus on innovation and quality, they have established themselves as a trusted provider of machinery and technology for the recycling and waste management industry. Their dedication to creating products that are both efficient and eco-friendly has earned them a reputation as a leader in the field of waste management.The introduction of the Plastic Crusher Machine is a testament to {Company Name}'s dedication to addressing the pressing issue of plastic pollution. By providing businesses and facilities with an effective and reliable tool for recycling plastic waste, they are helping to reduce the environmental impact of plastic pollution and move towards a more sustainable future. This machine is set to revolutionize the way plastic waste is managed, offering a practical and efficient solution that aligns with the growing demand for sustainable waste management practices.As the global conversation around plastic pollution continues to grow, the demand for effective and sustainable solutions for plastic waste management has never been greater. The Plastic Crusher Machine from {Company Name} is a significant step forward in this direction, offering businesses and facilities a practical and efficient tool for managing plastic waste. With its advanced technology, user-friendly design, and commitment to sustainability, this machine is poised to make a substantial impact on the way plastic waste is managed around the world.

Top Shredder Machine Prices: Find the Best Deals!

The demand for industrial shredder machines has been steadily increasing as businesses and industries look for efficient ways to manage their waste and recycling materials. In response to this growing trend, {Company Name} has announced the launch of their new range of shredder machines at competitive prices.With a strong focus on innovation and quality, {Company Name} has been a leading manufacturer of industrial equipment for over 20 years. Their commitment to providing reliable and durable machinery has earned them a solid reputation in the industry. The company's state-of-the-art manufacturing facilities and experienced engineering team enable them to produce high-quality shredder machines that meet the diverse needs of their customers.The newly launched shredder machines from {Company Name} are designed to handle a wide range of materials, including paper, cardboard, plastic, wood, and metal. The machines are equipped with advanced shredding technology to ensure efficient and consistent performance. In addition, {Company Name} offers customization options to tailor the machines to specific requirements, making them suitable for a variety of industrial applications.One of the key factors that sets {Company Name} apart from its competitors is its commitment to affordability. Despite the high-quality and advanced features of their shredder machines, the company has managed to keep the prices competitive. This has been made possible through strategic sourcing of materials, efficient manufacturing processes, and a focus on cost-effectiveness without compromising on quality.The prices of {Company Name}'s shredder machines vary depending on the model and capacity. However, the company has ensured that their pricing remains accessible to businesses of all sizes, from small enterprises to large industrial operations. This affordability factor is especially appealing to businesses looking to invest in sustainable waste management solutions without breaking the bank.In addition to competitive pricing, {Company Name} offers comprehensive after-sales support to their customers. This includes installation, training, maintenance, and technical assistance, ensuring that their clients can maximize the performance and lifespan of their shredder machines. The company's dedication to customer satisfaction has earned them a loyal and satisfied customer base.Furthermore, {Company Name} is committed to environmental responsibility, and their shredder machines are designed with sustainability in mind. By providing efficient waste management solutions, the company is contributing to the reduction of environmental impact and the promotion of a circular economy. This aligns with the increasing global focus on sustainability and environmental conservation.The launch of these new range of shredder machines at competitive prices by {Company Name} comes at a time when businesses are increasingly recognizing the importance of effective waste management and recycling. With the versatility, reliability, and affordability of these machines, {Company Name} is well-positioned to meet the evolving needs of the market and support businesses in their sustainability efforts.In conclusion, {Company Name} has once again proven its commitment to innovation, quality, and affordability with the launch of their new range of shredder machines at competitive prices. Their extensive experience in the industry, combined with a strong focus on customer satisfaction and environmental responsibility, makes {Company Name} a trusted choice for businesses looking for efficient waste management solutions. As industries continue to prioritize sustainability and efficient resource management, {Company Name} is poised to be a key player in providing the necessary equipment and support.

High-Quality Upvc Profile Extrusion Machines for Sale - Find Out More!

The global demand for UPVC profiles has been steadily increasing in recent years, and the market shows no signs of slowing down. In response to this growing demand, {Company Name} has developed a state-of-the-art UPVC profile extrusion machine that is set to revolutionize the industry.The {Company Name} is a leading manufacturer of plastic extrusion machinery, with a focus on providing innovative solutions for a wide range of industries. With a strong commitment to research and development, the company has built a reputation for delivering high-quality, reliable machinery that meets the needs of its customers.The new UPVC profile extrusion machine is the latest addition to {Company Name}'s product line, and it promises to deliver exceptional performance and efficiency. The machine is designed to produce UPVC profiles of various sizes and shapes with precision and consistency, making it ideal for a wide range of applications.One of the key features of the new machine is its advanced control system, which allows for easy and intuitive operation. This not only improves productivity and reduces downtime but also makes it easier for operators to achieve the desired results. In addition, the machine is equipped with state-of-the-art heating and cooling systems, ensuring that UPVC profiles are produced with uniform quality and precise dimensions.In addition to its technical capabilities, the new UPVC profile extrusion machine is also designed with sustainability in mind. {Company Name} has incorporated energy-efficient technology into the machine, reducing energy consumption and minimizing environmental impact. This commitment to sustainability reflects {Company Name}'s dedication to responsible manufacturing practices and its awareness of the importance of environmental conservation.{Company Name}'s dedication to customer satisfaction is evident in the after-sales support that comes with the new UPVC profile extrusion machine. The company's team of experts is on hand to provide training, technical assistance, and maintenance services, ensuring that customers can maximize the performance and lifespan of their machinery.The launch of the new UPVC profile extrusion machine represents a significant milestone for {Company Name}, further establishing its position as a leader in the industry. By combining cutting-edge technology with a commitment to customer satisfaction and sustainability, the company continues to set new standards for excellence in plastic extrusion machinery.With the global demand for UPVC profiles on the rise, {Company Name}'s new extrusion machine comes at a time when manufacturers are seeking efficient and reliable solutions to meet this demand. As the industry continues to evolve, {Company Name} remains at the forefront, driving innovation and delivering world-class machinery that exceeds customer expectations.In summary, {Company Name}'s new UPVC profile extrusion machine is set to make a significant impact on the industry, providing manufacturers with the tools they need to meet the growing demand for UPVC profiles. With its advanced technology, commitment to sustainability, and dedication to customer satisfaction, {Company Name} continues to demonstrate its leadership and vision in the field of plastic extrusion machinery.