Innovative Plastic Recycling Washing Machine: An Effective Solution for Waste Management

By:Admin

Enter {}, a leading manufacturer of plastic recycling equipment that is dedicated to providing innovative and sustainable solutions for the recycling industry. With over 20 years of experience in the field, {} has established itself as a trusted name in the industry, known for its high-quality products and exceptional customer service.

One of the latest offerings from {} is its state-of-the-art plastic recycling washing machine. This cutting-edge machine is designed to effectively remove impurities and contaminants from plastic waste, ensuring that the recycled materials meet the highest quality standards. The machine is equipped with advanced technologies that enable it to clean and wash a wide range of plastic materials, including PET bottles, HDPE containers, and other plastic packaging waste.

The plastic recycling washing machine from {} is designed with efficiency and sustainability in mind. It is equipped with a high-capacity water filtration system that minimizes water consumption and ensures that the washing process is environmentally friendly. In addition, the machine is equipped with advanced sensors and control systems that optimize the washing process, reducing energy consumption and operating costs.

One of the key features of the {} plastic recycling washing machine is its user-friendly design. The machine is equipped with a touch-screen interface that allows operators to easily monitor and control the washing process. It also features automated cleaning cycles and self-diagnostic capabilities, making it easy to maintain and operate.

In addition to its advanced features, the plastic recycling washing machine from {} is also designed with durability and reliability in mind. It is built with high-quality materials and components, ensuring that it can withstand the rigors of continuous use in a recycling facility. With proper maintenance and care, this machine is designed to provide years of reliable service, helping recycling facilities to maximize their productivity and efficiency.

In line with its commitment to sustainability, {} also offers comprehensive support and training services for its plastic recycling washing machine. The company provides training programs for operators and maintenance personnel, ensuring that they have the knowledge and skills to operate the machine safely and efficiently. In addition, {} offers a range of maintenance and support services to ensure that the machine operates at peak performance throughout its lifecycle.

With the introduction of its plastic recycling washing machine, {} is once again demonstrating its dedication to innovation and sustainability in the recycling industry. By providing cutting-edge solutions for plastic waste management, {} is helping to make a positive impact on the environment while also supporting the growth of the recycling industry.

In conclusion, the plastic recycling washing machine from {} is a testament to the company's commitment to providing innovative and sustainable solutions for the recycling industry. With its advanced features, user-friendly design, and robust construction, this machine is set to make a significant impact on the global effort to reduce plastic pollution and promote a more sustainable future. With {} leading the way, the future of plastic recycling looks brighter than ever before.

Company News & Blog

Efficient Plastic Bag Crusher Machine for Easy Waste Management

Plastic Bag Crusher Machine Revolutionizes Recycling EffortsIn a world where environmental sustainability is becoming increasingly important, [Company Name] is leading the charge with its innovative Plastic Bag Crusher Machine. This state-of-the-art technology is set to revolutionize the way plastic waste is managed and recycled, providing a practical solution to one of the world's most pressing environmental challenges.The Plastic Bag Crusher Machine, designed and manufactured by [Company Name], is an efficient and effective solution for reducing plastic waste. Equipped with a powerful motor and sharp blades, the machine is capable of shredding and crushing plastic bags and other plastic materials with ease. By reducing plastic waste into smaller, more manageable pieces, the machine makes it easier to process and recycle the plastic, ultimately contributing to a cleaner and healthier environment.One of the key features of the Plastic Bag Crusher Machine is its versatility. The machine can be used to crush a wide range of plastic materials, including shopping bags, plastic film, packaging materials, and more. This flexibility makes it an ideal solution for businesses, recycling centers, and municipalities looking to streamline their plastic waste management processes.Moreover, the machine is designed with safety and efficiency in mind. Its user-friendly interface and automatic shut-off feature ensure that the machine can be operated without any risk to the user. Additionally, its compact design and robust construction make it a reliable and long-lasting solution for any organization looking to enhance its recycling efforts.The Plastic Bag Crusher Machine is also in line with [Company Name]'s commitment to sustainability and environmental stewardship. As a leader in the manufacturing industry, the company has dedicated itself to developing technologies that not only improve operational efficiency but also minimize the impact on the environment. The Plastic Bag Crusher Machine is a testament to this commitment, offering a practical and sustainable solution for managing plastic waste.Beyond the environmental benefits, the Plastic Bag Crusher Machine also offers economic advantages for businesses and organizations. By streamlining their plastic waste management processes, companies can reduce their operational costs and contribute to a more circular economy. Additionally, by recycling plastic materials with the help of the machine, businesses can contribute to the production of new plastic products, further reducing the demand for virgin plastics and the associated environmental impact.The Plastic Bag Crusher Machine has already garnered attention and praise from industry experts and environmental advocates. Its innovative design and practical functionality make it a standout solution in the field of plastic waste management. With its potential to significantly reduce the environmental impact of plastic waste, the machine is a promising tool for organizations looking to enhance their sustainability efforts.In conclusion, the Plastic Bag Crusher Machine from [Company Name] is a game-changer in the field of plastic waste management. Its efficient and versatile design, coupled with its environmental and economic benefits, make it a valuable tool for businesses, recycling centers, and municipalities. As the global focus on environmental sustainability continues to grow, the Plastic Bag Crusher Machine stands as a beacon of innovation and progress in the ongoing effort to create a more sustainable future for the planet.

Efficient Single Stage Pelletizing Machine for Plastic Recycling

Single stage pelletizing machine (brand name removed) is set to revolutionize the pelletizing process for various industries, thanks to its cutting-edge technology and innovative design. The machine, developed by the global leader in industrial equipment manufacturing, promises to provide a more efficient and cost-effective solution for companies looking to streamline their production processes.The single stage pelletizing machine is designed to meet the increasing demand for high-quality pellets across a wide range of industries, including plastics, rubber, food processing, and pharmaceuticals. With its advanced features and capabilities, the machine is poised to set a new industry standard for pelletizing equipment.One of the key features of the single stage pelletizing machine is its ability to process a wide range of raw materials, including virgin and recycled plastics, rubber compounds, and food ingredients. This versatility makes it an ideal choice for companies looking to diversify their product offerings or improve their sustainability efforts by using recycled materials in their production processes.The machine also boasts a high-capacity output, allowing companies to increase their production volume without compromising on the quality of their pellets. This is especially beneficial for companies with growing demand for their products, as they can now rely on a single machine to meet their production needs.In addition to its high-capacity output, the single stage pelletizing machine is also equipped with advanced control systems that allow for precise adjustment of pellet size and shape. This level of customization ensures that companies can produce pellets that meet their exact specifications, whether they are used for injection molding, extrusion, or other manufacturing processes.Furthermore, the machine is designed with ease of maintenance in mind, featuring a user-friendly interface and durable components that minimize downtime and reduce the need for frequent repairs. This means that companies can rely on the machine to consistently produce high-quality pellets with minimal interruptions to their operations.With these advanced features and capabilities, the single stage pelletizing machine is expected to deliver significant benefits to companies across a range of industries. In particular, it will help companies improve their production efficiency, reduce their operational costs, and enhance the quality of their end products.{Company Name}, the manufacturer behind the single stage pelletizing machine, has a long-standing reputation for delivering innovative and reliable industrial equipment to companies worldwide. With a focus on research and development, the company is committed to continuously improving its products to meet the evolving needs of its customers.{Company Name} has a dedicated team of engineers and technicians who have worked tirelessly to develop the single stage pelletizing machine, ensuring that it meets the highest standards of quality and performance. Through extensive testing and refinement, the company has created a machine that is poised to make a significant impact on the pelletizing industry.As a global leader in industrial equipment manufacturing, {Company Name} is well positioned to introduce the single stage pelletizing machine to companies around the world. With a network of distributors and service centers in key markets, the company is able to provide comprehensive support to its customers, ensuring that they can fully maximize the benefits of the new machine.In conclusion, the single stage pelletizing machine from {Company Name} represents a major advancement in pelletizing technology, offering companies a more efficient and cost-effective solution for their production needs. With its advanced features, high-capacity output, and ease of maintenance, the machine is set to revolutionize the way companies produce pellets, setting a new industry standard for quality and performance.

Efficient and Sustainable Washing Line for Recycling

Recycle Washing Line is a leading provider of recycling solutions for the plastic industry. With a strong focus on innovation and sustainable practices, the company has been at the forefront of developing cutting-edge technology for processing and reusing plastic materials. Their state-of-the-art recycling washing line is designed to efficiently clean and transform used plastic materials into high-quality recycled pellets, which can then be used as raw material for a wide range of products. The washing line is equipped with advanced machinery that can effectively remove contaminants, such as dirt, labels, and other impurities, from the plastic material. This process is essential for ensuring that the recycled pellets meet the required quality standards and can be used in various manufacturing processes.The company’s commitment to sustainability is evident in the design and operation of the washing line. By repurposing used plastic materials, Recycle Washing Line is not only helping to reduce the amount of plastic waste in landfills but also minimizing the need for virgin plastic production. This, in turn, contributes to the conservation of natural resources and a reduction in the carbon footprint associated with plastic manufacturing.In addition to its environmental benefits, the washing line also offers economic advantages. By providing a reliable source of high-quality recycled pellets, Recycle Washing Line is helping businesses reduce their raw material costs while also improving their sustainability credentials. This is particularly important in today’s market, where consumers are increasingly prioritizing eco-friendly products and practices.Furthermore, the company’s dedication to innovation and continuous improvement has led to the development of washing line technology that is not only efficient but also flexible. This means that the washing line can accommodate a wide range of plastic materials, including PET, HDPE, and LDPE, among others. This versatility makes it an attractive solution for businesses operating in various sectors of the plastic industry.Moreover, Recycle Washing Line is committed to providing exceptional customer service and support. Their team of experts works closely with clients to understand their specific recycling needs and develop tailored solutions that align with their business objectives. Whether it’s a small-scale operation or a large-scale production facility, the company can design and implement a washing line system that meets the unique requirements of each client.For businesses looking to enhance their sustainability efforts and improve their bottom line, Recycle Washing Line offers a compelling solution. By investing in their state-of-the-art washing line technology, companies can effectively contribute to the circular economy while also realizing cost savings and operational efficiencies.In conclusion, Recycle Washing Line is a trusted partner for businesses seeking to implement sustainable and cost-effective recycling solutions. With their innovative washing line technology and commitment to customer satisfaction, the company is well-positioned to continue leading the way in the plastic recycling industry.

Find affordable extruder machine prices for your business needs

Extruder Machine Price Trends in the Modern MarketThe global extruder machine market is on the rise as manufacturers seek to streamline their production processes, increase efficiency, and reduce operational costs. With the advancements in technology and the growing demand for high-quality products, the extruder machine has become an essential tool for various industries such as food processing, plastic manufacturing, and chemical production.In recent years, there has been a significant increase in the production and sales of extruder machines, leading to a competitive market with various manufacturers offering a wide range of products. With this surge in supply, customers are now presented with numerous options when it comes to choosing the perfect extruder machine for their specific needs.One of the key factors that customers consider when purchasing an extruder machine is the price. The cost of an extruder machine can vary significantly depending on the manufacturer, specifications, and additional features. For example, a basic model from a lesser-known brand may have a much lower price compared to a high-end model from a well-established manufacturer.When it comes to price, customers must also take into account the long-term benefits and performance of the extruder machine. While a lower-priced machine may seem like a cost-effective option, it may not offer the same level of efficiency, reliability, and durability as a higher-priced model. Therefore, it is crucial for customers to carefully evaluate their production requirements and budget in order to make an informed decision.In line with this, {Company Name} has been a leading player in the extruder machine industry, offering a wide range of high-quality products to meet the diverse needs of its customers. With a strong focus on innovation and customer satisfaction, {Company Name} has established itself as a trusted manufacturer with a reputation for delivering top-notch extruder machines.{Company Name} takes pride in its commitment to providing cost-effective solutions without compromising on quality and performance. Its extensive product line includes a variety of extruder machines designed for different applications, ranging from food processing to plastic manufacturing. Each machine is engineered to deliver consistent results, high productivity, and energy efficiency, ensuring that customers get the best value for their investment.When it comes to pricing, {Company Name} understands the importance of offering competitive rates while maintaining the highest standards of excellence. The company strives to provide transparent pricing that reflects the quality and reliability of its products, allowing customers to make well-informed purchasing decisions. Furthermore, {Company Name} offers comprehensive support and after-sales service to ensure that customers get the most out of their investment in an extruder machine.In conclusion, the extruder machine market is experiencing a significant growth, driven by the increasing demand for advanced manufacturing solutions. As customers navigate through a myriad of choices, it is crucial for them to carefully evaluate the price, quality, and performance of extruder machines before making a purchase. With {Company Name} leading the way in providing cost-effective, high-quality products, customers can rest assured that they are investing in a reliable and efficient extruder machine.As the demand for extruder machines continues to rise, {Company Name} remains dedicated to delivering cutting-edge solutions that empower manufacturers to enhance their production capabilities and achieve sustainable growth. With its unwavering commitment to excellence, {Company Name} is poised to remain a prominent player in the extruder machine market, offering innovative products and unparalleled value to its customers.

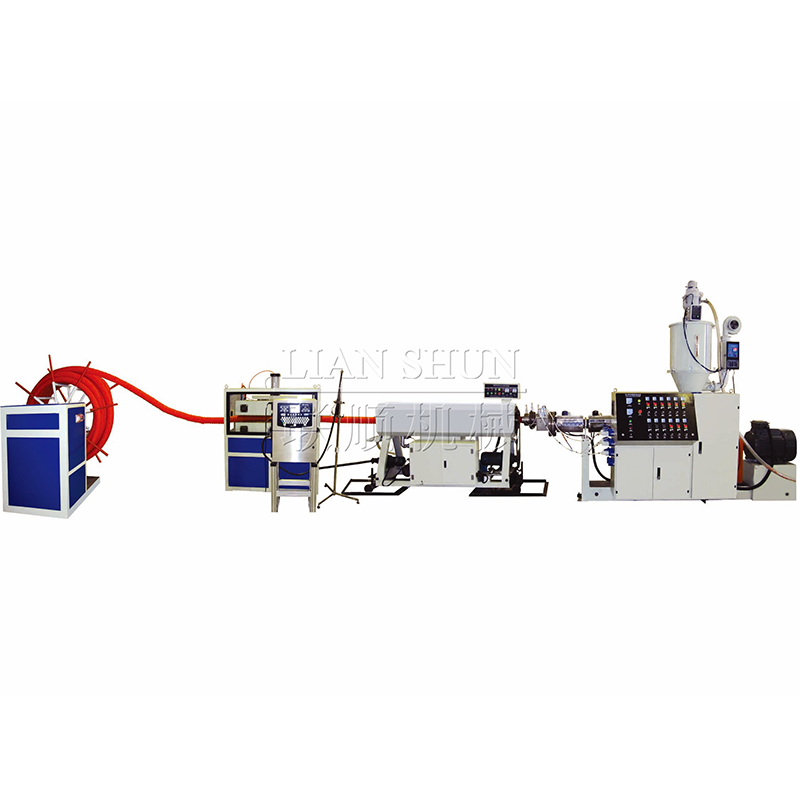

High-Quality Pprc Pipe Machine for Efficient Pipe Manufacturing Process

[Company Introduction]Pprc Pipe Machine (need remove brand name) is a renowned manufacturer of high-quality pipe production machinery. With years of experience and expertise in the industry, the company has established itself as a leader in providing innovative and reliable solutions for the production of PPRC pipes. Its state-of-the-art manufacturing facility and a team of skilled professionals have enabled the company to deliver cutting-edge products and services to its global clientele.As a forward-thinking and customer-centric organization, Pprc Pipe Machine is dedicated to continuous research and development to enhance its product portfolio and stay ahead of industry trends. The company's commitment to quality, precision, and efficiency has earned it a stellar reputation in the market, making it the preferred choice for businesses seeking top-of-the-line machinery for their pipe production needs.[News Content]Pprc Pipe Machine Unveils New State-of-the-Art Machinery for PPRC Pipe ProductionPprc Pipe Machine is proud to announce the launch of its latest range of PPRC pipe production machinery, designed to meet the evolving needs of the industry. The new machines incorporate cutting-edge technology and advanced features that offer enhanced efficiency, flexibility, and precision in the manufacturing process.The company's new line of machinery includes extruders, molds, cooling tanks, haul-off units, cutting machines, and other auxiliary equipment, all of which are engineered to deliver superior performance and optimal output. These machines are capable of producing a wide range of PPRC pipe specifications, catering to the diverse requirements of the market.One of the key highlights of the new machinery is its advanced control system, which provides operators with seamless monitoring and adjustment capabilities for each stage of the production process. This not only ensures consistent quality and dimensional accuracy of the pipes but also increases overall productivity and reduces downtime.In addition to its technical prowess, Pprc Pipe Machine's new machinery is designed with a focus on energy efficiency and sustainability. The company has incorporated innovative process technologies and materials to minimize energy consumption and waste generation, aligning with its commitment to environmental responsibility.Furthermore, Pprc Pipe Machine offers comprehensive training and technical support to its clients, empowering them to maximize the potential of the new machinery and optimize their production operations. The company's team of experts is available to provide guidance on installation, operation, and maintenance, ensuring smooth integration of the machines into the clients' facilities.Commenting on the launch of the new machinery, a spokesperson for Pprc Pipe Machine stated, "We are thrilled to introduce our latest range of PPRC pipe production machinery, which represents the culmination of our continuous efforts to push the boundaries of innovation and excellence. With these new machines, we aim to set a new standard in the industry, empowering our clients to achieve greater efficiency and competitiveness in their operations."The spokesperson further emphasized the company's unwavering commitment to customer satisfaction and its dedication to delivering reliable and high-performing machinery that meets the dynamic needs of the market.The launch of the new machinery is expected to further elevate Pprc Pipe Machine's position as a leading provider of pipe production solutions and reinforce its status as a trusted partner for businesses seeking cutting-edge technology and exceptional quality in their operations. With a strong track record of success and a focus on continuous improvement, the company is poised to continue shaping the future of the PPRC pipe manufacturing industry.

Innovative Plastic Recycling Washing Machine: An Effective Solution for Waste Management

Plastic recycling is a critical component of the global effort to reduce environmental pollution and landfill waste. Recycling plastic not only helps to keep our planet clean, but also conserves valuable resources and reduces the carbon footprint associated with producing new plastics. With the increasing demand for recycled plastic materials, the need for efficient and effective plastic washing machines has become more important than ever before.Enter {}, a leading manufacturer of plastic recycling equipment that is dedicated to providing innovative and sustainable solutions for the recycling industry. With over 20 years of experience in the field, {} has established itself as a trusted name in the industry, known for its high-quality products and exceptional customer service.One of the latest offerings from {} is its state-of-the-art plastic recycling washing machine. This cutting-edge machine is designed to effectively remove impurities and contaminants from plastic waste, ensuring that the recycled materials meet the highest quality standards. The machine is equipped with advanced technologies that enable it to clean and wash a wide range of plastic materials, including PET bottles, HDPE containers, and other plastic packaging waste.The plastic recycling washing machine from {} is designed with efficiency and sustainability in mind. It is equipped with a high-capacity water filtration system that minimizes water consumption and ensures that the washing process is environmentally friendly. In addition, the machine is equipped with advanced sensors and control systems that optimize the washing process, reducing energy consumption and operating costs.One of the key features of the {} plastic recycling washing machine is its user-friendly design. The machine is equipped with a touch-screen interface that allows operators to easily monitor and control the washing process. It also features automated cleaning cycles and self-diagnostic capabilities, making it easy to maintain and operate.In addition to its advanced features, the plastic recycling washing machine from {} is also designed with durability and reliability in mind. It is built with high-quality materials and components, ensuring that it can withstand the rigors of continuous use in a recycling facility. With proper maintenance and care, this machine is designed to provide years of reliable service, helping recycling facilities to maximize their productivity and efficiency.In line with its commitment to sustainability, {} also offers comprehensive support and training services for its plastic recycling washing machine. The company provides training programs for operators and maintenance personnel, ensuring that they have the knowledge and skills to operate the machine safely and efficiently. In addition, {} offers a range of maintenance and support services to ensure that the machine operates at peak performance throughout its lifecycle.With the introduction of its plastic recycling washing machine, {} is once again demonstrating its dedication to innovation and sustainability in the recycling industry. By providing cutting-edge solutions for plastic waste management, {} is helping to make a positive impact on the environment while also supporting the growth of the recycling industry.In conclusion, the plastic recycling washing machine from {} is a testament to the company's commitment to providing innovative and sustainable solutions for the recycling industry. With its advanced features, user-friendly design, and robust construction, this machine is set to make a significant impact on the global effort to reduce plastic pollution and promote a more sustainable future. With {} leading the way, the future of plastic recycling looks brighter than ever before.

Efficient and Effective Plastic Bottle Washing Plant

(Company Name) launches state-of-the-art PET Bottle Washing Plant to tackle plastic waste(Location) - In a bid to contribute to the global effort in tackling plastic waste and promoting environmental sustainability, (Company Name) has unveiled its new PET Bottle Washing Plant. This cutting-edge facility is set to revolutionize the recycling industry by providing a sustainable solution for the recycling of PET bottles and reducing the environmental impact of plastic waste.The PET Bottle Washing Plant is the latest addition to (Company Name)'s diverse portfolio of environmental sustainability initiatives. With a strong commitment to creating a greener and cleaner future, the company has invested in advanced technologies and innovative processes to develop this state-of-the-art facility.The plant is designed to process and recycle PET bottles, which are widely used for packaging in the beverage and food industries. Through a series of stringent washing, sorting, and decontamination processes, the facility can efficiently transform used PET bottles into clean, high-quality flakes that can be used for the production of a wide range of products.One of the key features of the PET Bottle Washing Plant is its advanced washing and decontamination technology, which ensures that the recycled PET flakes meet the highest quality standards. By removing impurities and contaminants from the collected PET bottles, the facility can produce clean and food-grade recycled materials that are safe for use in various consumer products.The plant also incorporates an automated sorting system, which enables the efficient separation of different types of plastics. This not only enhances the recycling process but also minimizes the amount of non-recyclable materials that end up in landfills or the environment."We are proud to introduce our PET Bottle Washing Plant as part of our ongoing commitment to sustainability and environmental stewardship," said [Spokesperson's Name], CEO of (Company Name). "With this facility, we aim to set new standards for PET bottle recycling and contribute to the global effort in reducing plastic waste and promoting the circular economy."In addition to its technological advancements, the PET Bottle Washing Plant is also designed with sustainability in mind. The facility has implemented a closed-loop water system to minimize water consumption and reduce the environmental impact of the recycling process. Furthermore, the plant is powered by renewable energy sources, further reducing its carbon footprint and contributing to a more sustainable operation.The launch of the PET Bottle Washing Plant aligns with (Company Name)'s broader mission to create a positive impact on the environment and communities it serves. By investing in sustainable initiatives and embracing responsible business practices, the company strives to be a leader in promoting environmental conservation and circular economy principles.As the global demand for recycled materials continues to grow, the PET Bottle Washing Plant is poised to play a pivotal role in meeting this demand while addressing the pressing issue of plastic waste. By providing a reliable and sustainable solution for the recycling of PET bottles, (Company Name) aims to make a significant contribution to the global sustainability agenda.With the launch of the PET Bottle Washing Plant, (Company Name) is not only demonstrating its commitment to environmental sustainability but also setting a new standard for the recycling industry. Through innovation, advanced technology, and a dedication to responsible practices, the company is taking a proactive stance in tackling the challenges of plastic waste and paving the way for a more sustainable future.

Find Plastic Extruders Near Your Location for All Your Production Needs

Plastic Extruders Near Me are a vital component of the manufacturing process for various plastic products. They are utilized in a wide range of industries, including packaging, construction, automotive, and consumer goods. These machines are essential for shaping and forming raw plastic materials into a variety of products, from pipes and sheets to profiles and films.One of the leading suppliers of plastic extruders in the United States is {}. Established in 1990, {} has built a reputation for providing high-quality extrusion equipment and exceptional customer service. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, {} is dedicated to meeting the needs of its customers and delivering top-of-the-line plastic extrusion solutions.The company's extensive product line includes a wide range of extruders, from single-screw and twin-screw extruders to multi-layer co-extrusion lines. These machines are designed to accommodate various types of raw materials, including polyethylene, polypropylene, PVC, and more. Whether the application requires standard extrusion processes or custom solutions, {} has the expertise and resources to meet the unique demands of its customers.In addition to its impressive range of plastic extruders, {} also offers comprehensive technical support and after-sales service. The company's team of engineers provides assistance with installation, training, maintenance, and troubleshooting, ensuring that customers can maximize the performance and lifespan of their extrusion equipment. With a commitment to customer satisfaction, {} goes above and beyond to ensure that its clients have the support they need to succeed in their manufacturing operations.Furthermore, {}'s dedication to innovation and continuous improvement is evident in its investment in research and development. The company is constantly exploring new technologies and methods to enhance the efficiency, productivity, and sustainability of its extrusion equipment. By staying at the forefront of industry advancements, {} is able to offer cutting-edge solutions that enable its customers to remain competitive in a rapidly evolving market.The company's customer-centric approach and unwavering commitment to quality have earned {} a strong reputation in the plastic extrusion industry. Whether serving small businesses or large-scale manufacturers, {} is known for its reliability, integrity, and professionalism. Customers can trust that {} will deliver the right extrusion solution for their specific needs, with a focus on precision, performance, and longevity.With a nationwide network of sales and service professionals, {} is well-positioned to serve customers across the United States. This extensive reach allows the company to provide responsive and personalized support to clients in various regions, ensuring that they receive timely assistance and expertise. As a result, {} has become a trusted partner for businesses seeking dependable and efficient plastic extrusion equipment.In conclusion, plastic extruders play a critical role in the production of a wide range of plastic products, and {} stands out as a reputable and reliable provider of extrusion solutions. With its extensive product line, technical expertise, and dedication to customer satisfaction, the company continues to set the standard for excellence in the industry. Whether customers are in need of a new extruder, technical support, or custom solutions, they can count on {} to deliver the highest level of quality and service.

High-quality WPC Making Machine for Efficient Production

WPC Making Machine revolutionizing the manufacturing industryIn the ever-evolving world of technology and innovation, the WPC Making Machine has emerged as a game-changer in the manufacturing industry. This advanced machine, developed by {}, has streamlined the process of producing Wood-Plastic Composite (WPC) materials, offering unprecedented efficiency, precision, and versatility.{} is a leading manufacturer of industrial machinery, renowned for its commitment to quality, innovation, and customer satisfaction. With a strong focus on research and development, the company has continually pushed the boundaries of what is possible in the manufacturing sector. The WPC Making Machine is a testament to {}'s dedication to pioneering new technologies that enhance productivity and drive progress.The WPC Making Machine is designed to meet the growing demand for WPC materials, which are widely used in construction, automotive, and consumer goods industries. By blending wood fibers or flour with thermoplastics, WPC materials offer the natural look and feel of wood combined with the durability and low maintenance of plastic. As a result, they have become a popular choice for a wide range of applications, from decking and fencing to furniture and packaging.One of the key advantages of the WPC Making Machine is its ability to precisely control the mixing and extrusion process, ensuring that the resulting WPC materials meet the highest standards of quality and consistency. This level of precision is made possible by {}'s cutting-edge technology, which enables real-time monitoring and adjustment of critical parameters such as temperature, pressure, and material flow. As a result, manufacturers can produce WPC materials with the exact properties required for their specific applications, whether it's enhanced strength, weather resistance, or colorfastness.Furthermore, the WPC Making Machine offers exceptional versatility, allowing for the production of a wide variety of WPC products, from simple profiles and sheets to more complex structures and composites. This flexibility is a major advantage for manufacturers seeking to tap into the growing market for WPC materials and capitalize on the trend towards sustainable and eco-friendly alternatives to traditional materials.In addition to its technical capabilities, the WPC Making Machine also stands out for its efficiency and cost-effectiveness. By automating and optimizing the production process, {} has enabled manufacturers to significantly reduce waste, energy consumption, and labor costs, while increasing throughput and overall productivity. This not only benefits individual businesses but also contributes to the industry's overall sustainability and competitiveness.As the demand for WPC materials continues to grow, driven by concerns about deforestation, plastic pollution, and the need for more sustainable solutions, the WPC Making Machine is poised to play a pivotal role in shaping the future of manufacturing. With its advanced capabilities, versatility, and efficiency, it offers a compelling solution for businesses looking to stay ahead of the curve and meet the evolving needs of customers and the market.{}'s commitment to innovation and excellence has positioned the company as a leader in the field of industrial machinery, and the WPC Making Machine is a prime example of its forward-thinking approach to product development. By empowering manufacturers to produce high-quality WPC materials with greater efficiency and versatility, this cutting-edge machine is driving the industry towards a more sustainable, profitable, and competitive future.

High-Quality Pvc Powder Mixing Machine for Efficient Production

PVC Powder Mixing Machine Revolutionizing the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, innovation is key to staying ahead of the game. One company, {}, is leading the way with their revolutionary PVC powder mixing machine. This state-of-the-art equipment is changing the way PVC products are manufactured, making the process more efficient and cost-effective.The PVC powder mixing machine is designed to mix PVC powder and additives to produce a homogeneous mixture before further processing. This crucial step ensures that the final product meets the highest quality standards and is free from any inconsistencies. The machine is equipped with advanced technology and precision engineering, making it a game-changer for manufacturers in the PVC industry.The company behind this innovative machine, {}, has been a pioneer in the field of manufacturing equipment for over 20 years. Their commitment to research and development has led to the creation of cutting-edge solutions for various industries, including PVC manufacturing. With a team of skilled engineers and experts, they have continuously improved their products to meet the ever-changing demands of the market.The PVC powder mixing machine is a testament to the company's dedication to innovation and excellence. It is designed to save manufacturers time and money by streamlining the mixing process and ensuring a consistent end product. This not only improves the overall quality of the PVC products but also enhances the efficiency of the manufacturing process.One of the key features of the PVC powder mixing machine is its user-friendly interface. The machine is easy to operate, reducing the need for extensive training and allowing manufacturers to get up and running quickly. In addition, it is equipped with safety features to protect workers and prevent accidents in the workplace.Furthermore, the machine is designed to minimize waste, which is a significant issue in the manufacturing industry. By ensuring thorough and even mixing of PVC powder and additives, the machine reduces the likelihood of product defects and rejects. This, in turn, leads to cost savings for manufacturers and a more sustainable approach to production.The PVC powder mixing machine is also customizable to meet the specific needs of different manufacturers. Whether it's a small-scale operation or a large production facility, the machine can be tailored to fit the requirements of the customer. This flexibility makes it an attractive investment for a wide range of businesses in the PVC industry.With the PVC powder mixing machine, manufacturers can expect to see improvements in their overall production efficiency. The machine's ability to consistently produce high-quality mixtures in a shorter timeframe means that businesses can increase their output without compromising on the quality of their products. This gives them a competitive edge in the market and can lead to increased profitability.In conclusion, the PVC powder mixing machine developed by {} is a game-changer for the manufacturing industry. Its advanced technology, user-friendly interface, and customizable features make it a valuable asset for PVC manufacturers looking to improve their production processes. With this innovative equipment, businesses can expect to see significant cost savings, improved product quality, and enhanced efficiency. As the manufacturing industry continues to evolve, solutions like the PVC powder mixing machine will play a crucial role in shaping its future.